[AutoCAD、韩国CADian、中望CAD、浩辰CAD]世界上功能最为强大的线切割软件与雕铣软件,同时生成3B代码和G代码(XYZIJK格式、XYZR格式),绝对坐标和增量坐标格式;实现快、中、慢走丝跳步的全自动编程,适用于 WINxp,WIN7,WIN8,WIN10,AutoCAD2004~2020,软件精确到0.0001 U盘或移动硬盘加密,随身携带方便,适合多台电脑使用

全套软件下载:

www.aero-cad.com/up_file/CAD线切割编程软件.rar

www.aero-cad.com/up_file/cad线切割跳步编程录像.exe

www.aero-cad.com/up_file/cad跳步编程录像视频.exe

www.aero-cad.com/up_file/CAD线切割修形编程录像.exe

www.aero-cad.com/up_file/CAD跳步编程操作录像(中望版).exe

多特网下载:

http://www.duote.com/soft/67504.html

非凡软件站下载:

http://www.crsky.com/soft/45427.html

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

AutoCAD全自动线切割与雕铣软件

让中国再伟大

宇航CAD,引领新一波工业革命浪潮

欢迎使用中国国内功能最强的线切割与雕铣软件.此软件在AutoCAD2004上开发,适用于AutoCAD2004及以上版本.中望CAD、浩辰CAD 适用于2012版及以上版本,韩国CADian适用于2020版及以上版本.这套数控线切割软件适合所有线切割机器,无论快走丝、中走丝、慢走丝,国产、进口. 适合所有数控铣床,无论国产、进口.

线切割试用程序:

nc-l-arc.vlx 支持直线(line)和圆弧(arc)

nc-l-arc-pl.vlx 支持直线(line),圆弧(arc)和多段线(pline)

Check.vlx----由G代码加工程序画出DWG图

Check3B.vlx----由3B代码加工程序画出DWG图

永久免费使用程序:

wire-circle.vlx 慢走丝割圆,生成G码,XYZIJK格式

IJKR-circle.vlx 慢走丝割圆,生成G码,XYZIJK格式和XYZR格式

3bwire-circle.vlx 快走丝割圆,生成3B码

安装使用说明:

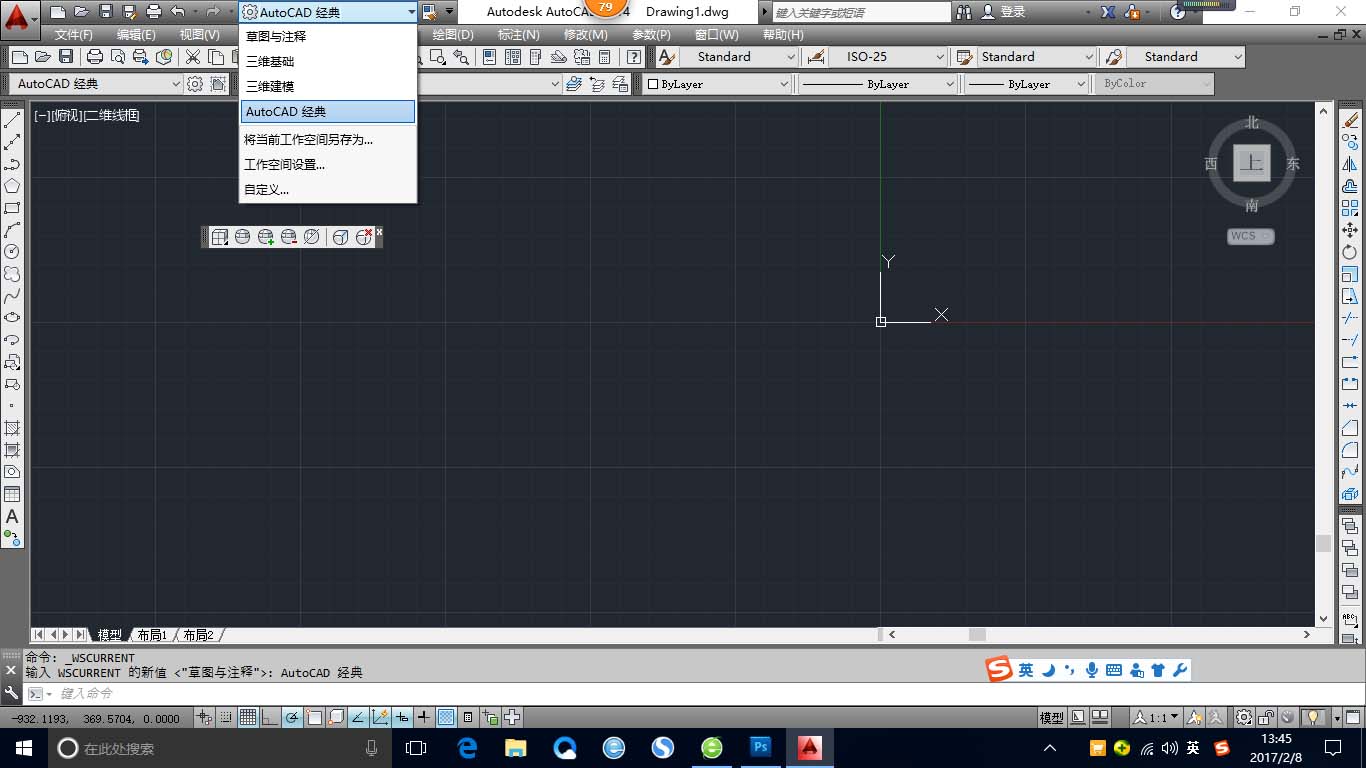

将AUTOCAD的介面设为经典模式(菜单模式):

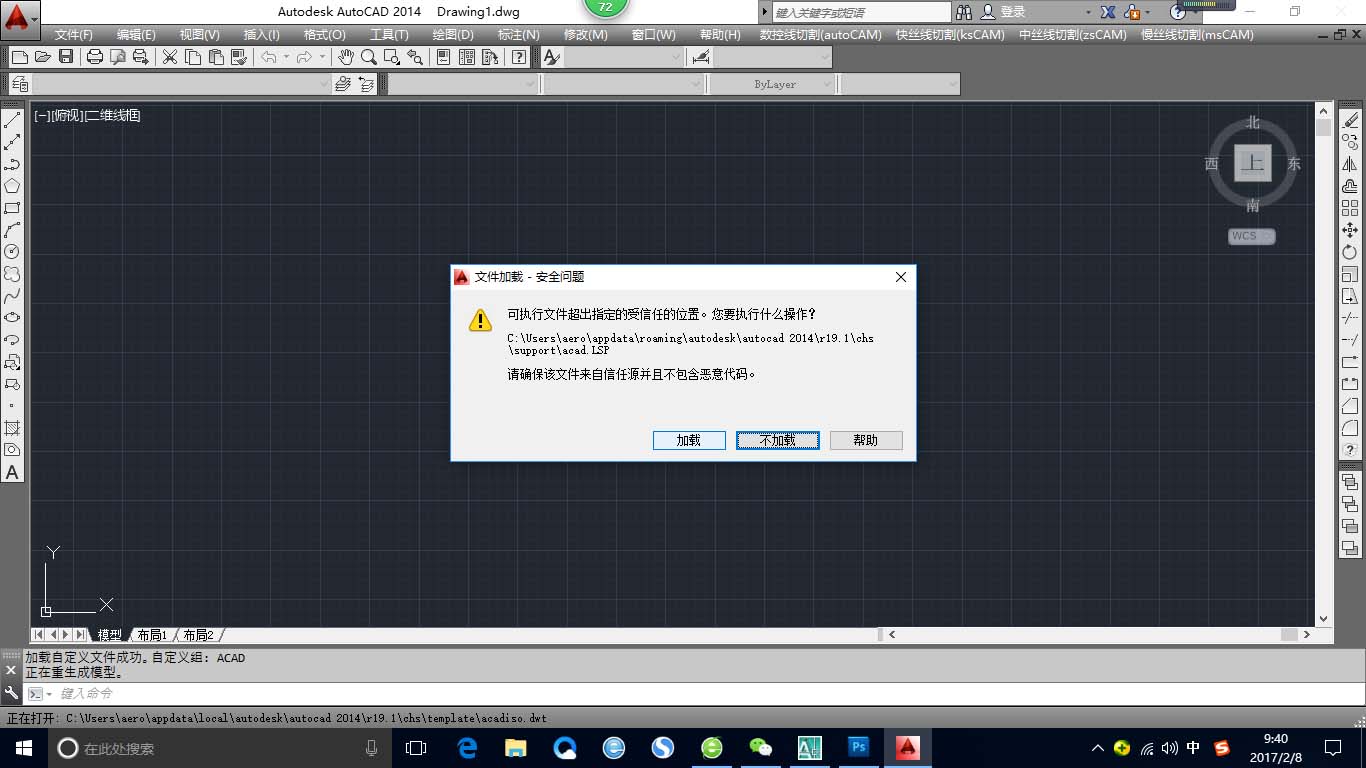

把所有文件拷贝到AUTOCAD的安装目录下,启动AUTOCAD。点下图中的“加载”按钮。

1.在AutoCAD中增加一个命令:

在AutoCAD中,如果要加载运行nc-l-arc-pl.vlx,点菜单下的"工具tools",点"加载应用程序(load application...)",再点此程序nc-l-arc-pl.vlx,点"加载load"按钮,点"关闭close"按钮. 在AutoCAD的命令(Command:)下,输入nc-l-arc-pl命令,输入文件名,就可自动生成NC加工程序。运行其它vlx程序类似.

2.让增加的命令永存于AutoCAD中:

为使nc-l-arc-pl命令在AutoCAD中永存,点"加载应用程序(load application...)"后,再点"内容",点"添加",点此程序nc-l-arc-pl.vlx,再点"添加",点"关闭close"按钮.下次运行AutoCAD就无须再加载nc-l-arc-pl.vlx, nc-l-arc-pl命令将永驻于AUTOCAD中.

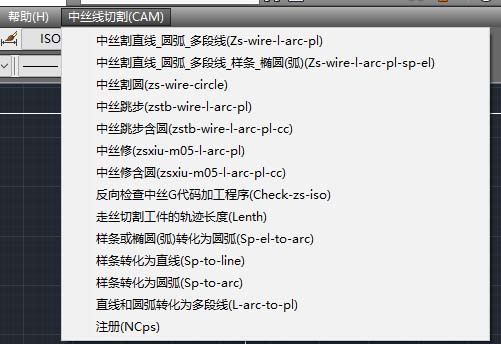

3.在AutoCAD中增加和应用下拉式菜单:

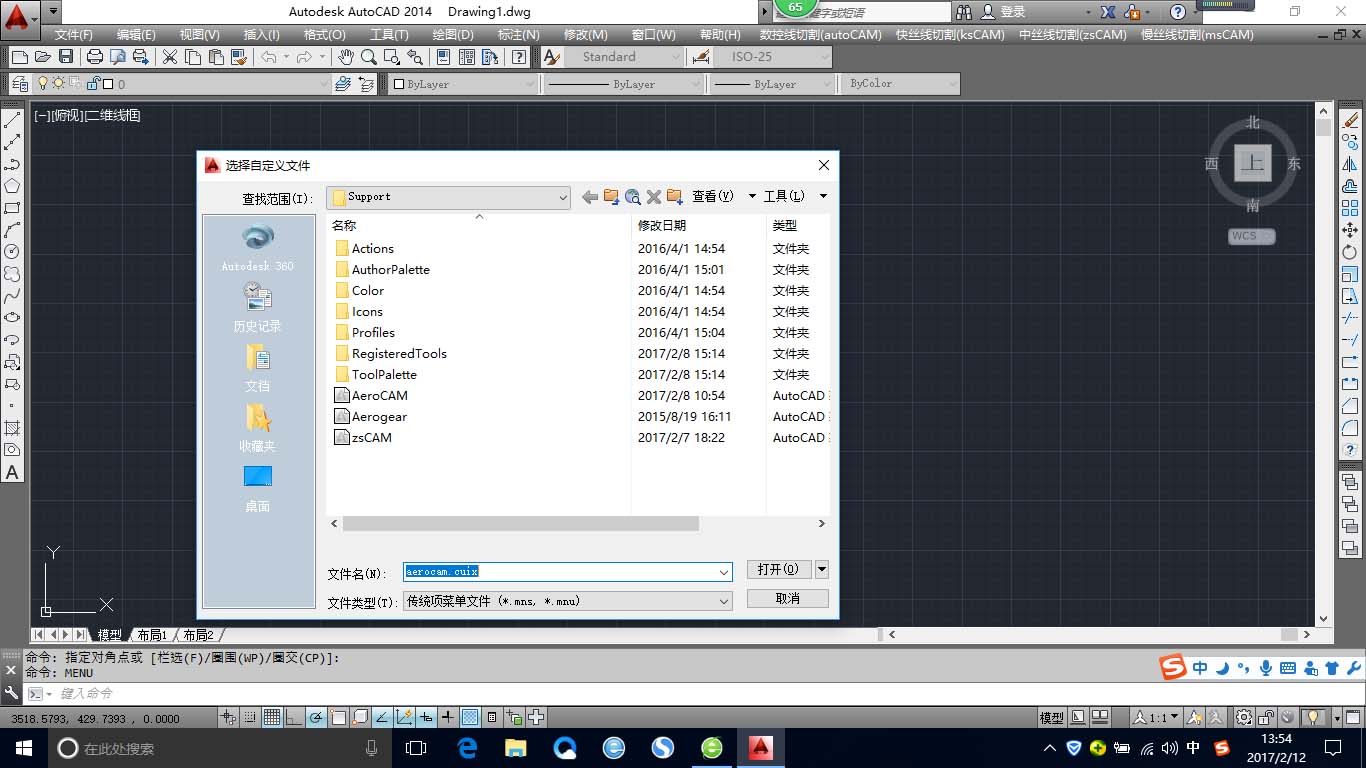

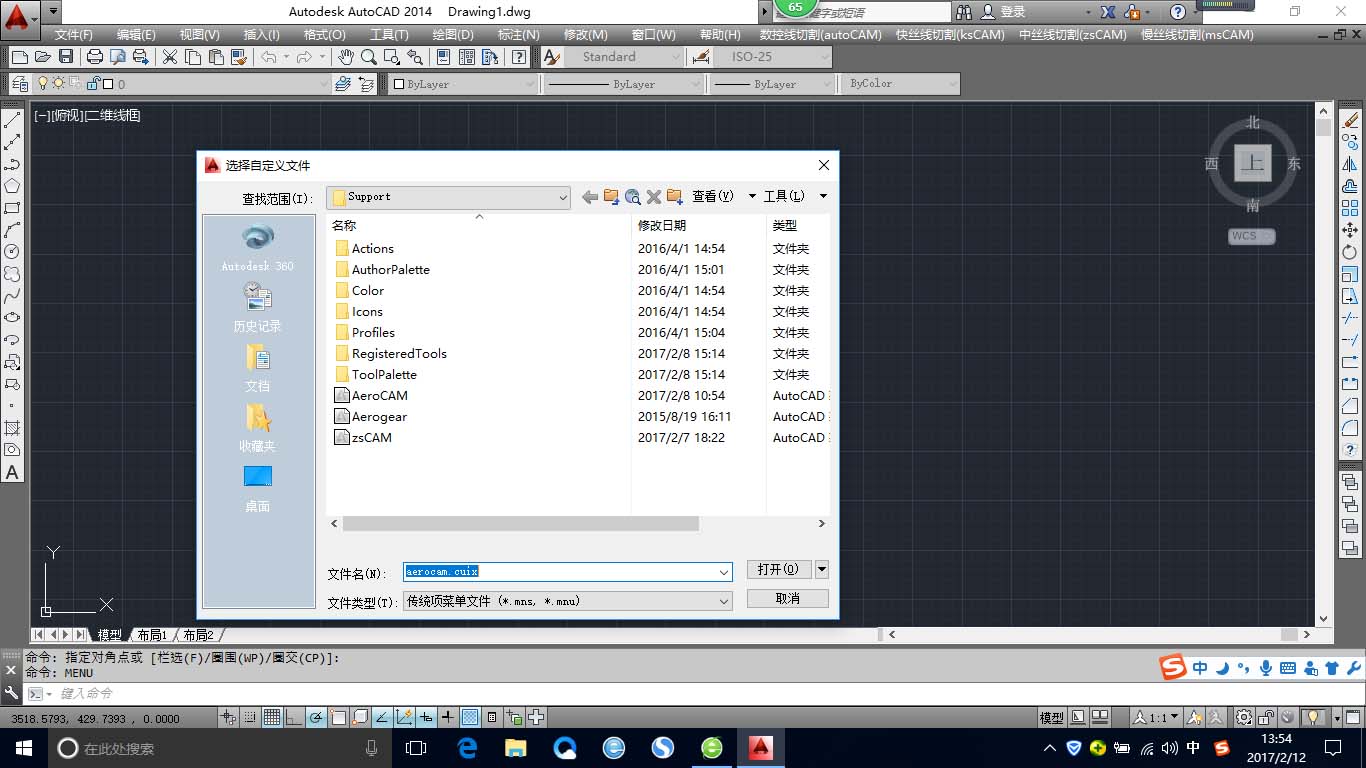

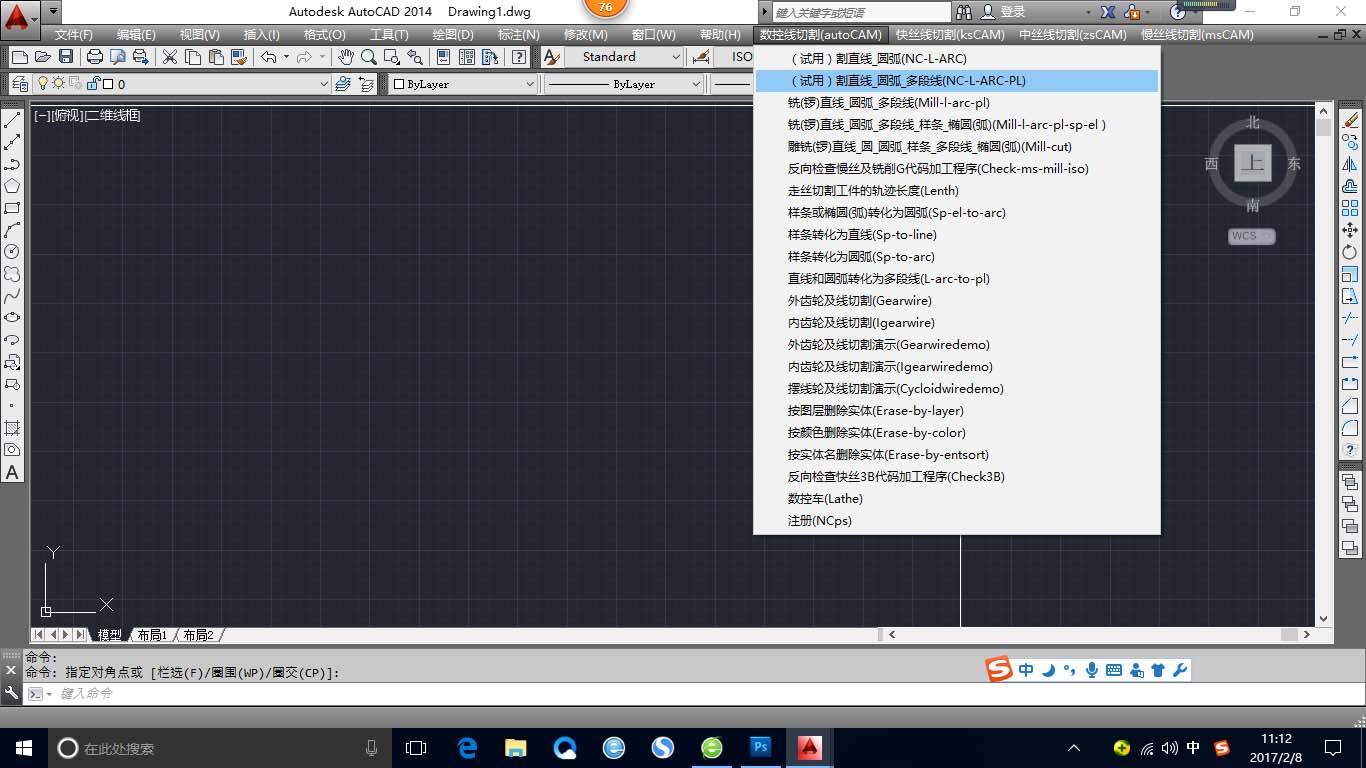

把AeroCAM.mnu拷贝到AutoCAD的SUPPORT下,在AutoCAD的命令(Command:)下,输入menu,点AeroCAM.mnu,加载菜单,就可点击菜单命令.

线切割试用程序:nc-l-arc.vlx 支持直线(line)和圆弧(arc)

线切割试用程序:nc-l-arc-pl.vlx 支持直线(line),圆弧(arc)和多段线(pline)

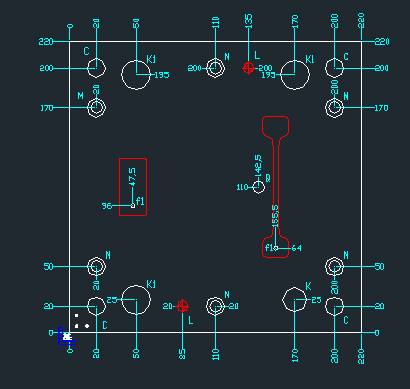

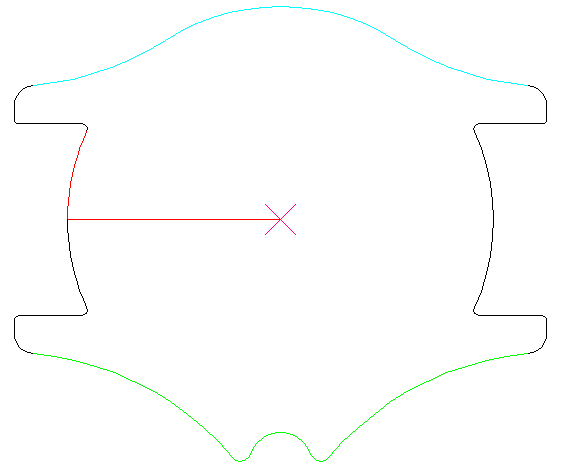

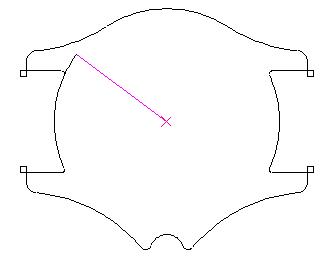

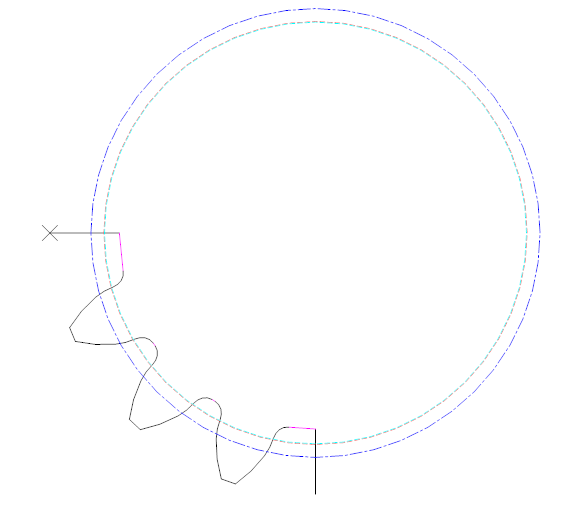

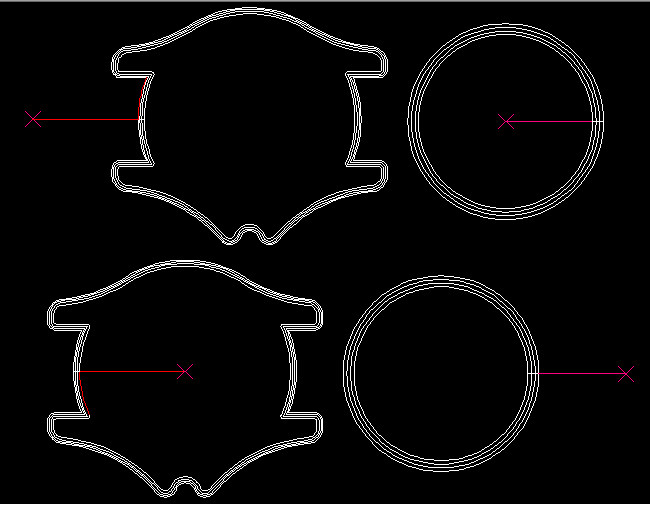

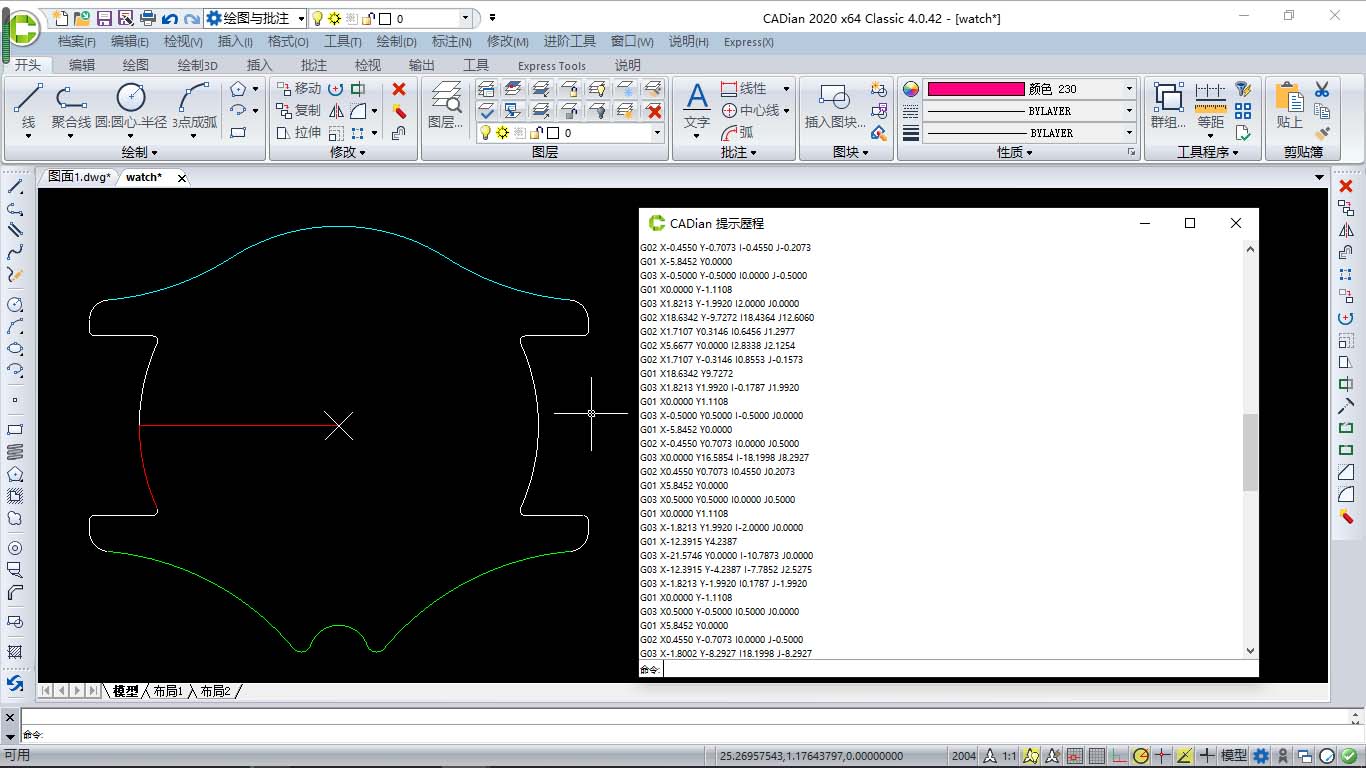

nc-l-arc.vlx----线切割试用程序,例如线切割如下表壳外轮廓的模具内腔,轮廓是直线(line)和圆弧(arc)组成的封闭轮廓。

红色的是连为一体的PLINE线,确保顺时针切割.

X叉是AUTOCAD的point点,作为线切割起点,穿丝孔(CAD系统参数pdmode=3,pdsize=2).封闭轮廓由直线(line)和圆弧(arc)组成。加载后,执行nc-l-arc命令,只需输入文件名,选择所有的实体图形。选择时无须按顺序,只须框选所有的实体,或在select object提示下,输入all。然后自动生成如下线切割加工程序:watch.cam

M02

线切割轮廓可以是封闭的,也可以是开放的。线切割补偿由机床实现,也可offset路径。以上线切割代码文件存入wire-*.cam中,可用windows记事本打开。起始点point不能少,必须是(直线,圆弧和样条...)的端点,用AutoCAD的END(端点)方式捕捉。

如果要清角,可修改路径:

重新运行nc-l-arc命令,自动生成如下线切割加工程序:watch1.cam

wire-watch1

G90G17G40

G92G00 X-37.1726 Y182.0162

G01 X-53.2764 Y193.8765

G03 X-55.3724 Y173.7235 I16.1038 J-11.8603

G02 X-55.8274 Y173.0162 I-0.4550 J-0.2073

G01 X-63.1726 Y173.0162

G01 X-63.1726 Y174.0162

G01 X-62.1726 Y174.0162

G01 X-62.1726 Y171.4054

G03 X-60.3513 Y169.4134 I2.0000 J0.0000

G02 X-41.7171 Y159.6862 I-2.4611 J-27.4270

G03 X-40.0064 Y160.0008 I0.7661 J0.6428

G02 X-34.3388 Y160.0008 I2.8338 J-0.9846

G03 X-32.6281 Y159.6862 I0.9446 J0.3282

G02 X-13.9939 Y169.4134 I21.0954 J-17.6998

G03 X-12.1726 Y171.4054 I-0.1787 J1.9920

G01 X-12.1726 Y174.0162

G01 X-11.1726 Y174.0162

G01 X-11.1726 Y173.0162

G01 X-18.5178 Y173.0162

G02 X-18.9728 Y173.7235 I0.0000 J0.5000

G03 X-18.9728 Y190.3089 I-18.1998 J8.2927

G02 X-18.5178 Y191.0162 I0.4550 J0.2073

G01 X-11.1726 Y191.0162

G01 X-11.1726 Y190.0162

G01 X-12.1726 Y190.0162

G01 X-12.1726 Y192.6270

G03 X-13.9939 Y194.6190 I-2.0000 J0.0000

G02 X-26.3853 Y198.8577 I2.4611 J27.4270

G03 X-47.9599 Y198.8577 I-10.7873 J-16.8414

G02 X-60.3513 Y194.6190 I-14.8526 J23.1883

G03 X-62.1726 Y192.6270 I0.1787 J-1.9920

G01 X-62.1726 Y190.0162

G01 X-63.1726 Y190.0162

G01 X-63.1726 Y191.0162

G01 X-55.8274 Y191.0162

G02 X-55.3724 Y190.3089 I0.0000 J-0.5000

G40G01 X-37.1726 Y182.0162

M02

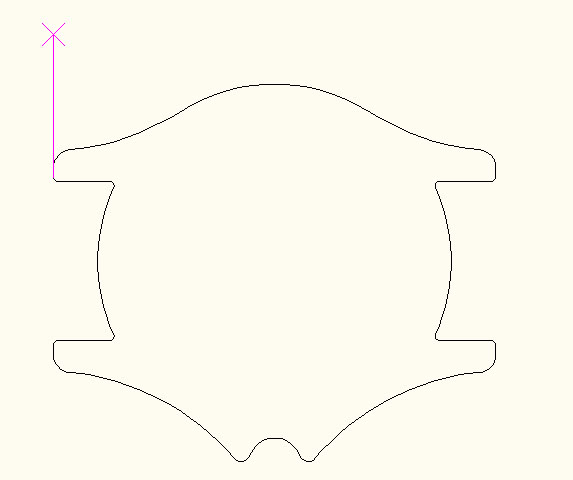

假定表壳模具型腔的厚度为5mm,拔模斜度为10度,那么上下轮廓的等距偏移量dist=5*tan(10)= 0.8816349, 以 L-arc-to-pl.vlx程序(或者pedit的join连接命令)将上面的直线和圆弧转化为多段线pline,

将上图offset 0.8816349,

加载并运行nc-l-arc-pl.vlx,选红色的路径和起始点X,得如下程序:watch2.cam

wire-watch2

G90G17G40

G92G00 X-37.1726 Y182.0162

G01 X-53.0730 Y192.6317

G03 X-54.5701 Y174.0891 I15.9004 J-10.6155

G02 X-55.8274 Y172.1346 I-1.2573 J-0.5729

G01 X-64.0542 Y172.1346

G01 X-64.0542 Y174.8978

G01 X-61.2910 Y174.8978

G01 X-61.2910 Y171.4054

G03 X-60.2726 Y170.2915 I1.1184 J0.0000

G02 X-41.0417 Y160.2529 I-2.5399 J-28.3051

G03 X-40.8392 Y160.2901 I0.0907 J0.0761

G02 X-33.5060 Y160.2901 I3.6666 J-1.2739

G03 X-33.3035 Y160.2529 I0.1118 J0.0388

G02 X-14.0726 Y170.2915 I21.7708 J-18.2664

G03 X-13.0542 Y171.4054 I-0.1000 J1.1139

G01 X-13.0542 Y174.8978

G01 X-10.2910 Y174.8978

G01 X-10.2910 Y172.1346

G01 X-18.5178 Y172.1346

G02 X-19.7751 Y174.0891 I0.0000 J1.3816

G03 X-19.7751 Y189.9433 I-17.3975 J7.9271

G02 X-18.5178 Y191.8978 I1.2573 J0.5729

G01 X-10.2910 Y191.8978

G01 X-10.2910 Y189.1346

G01 X-13.0542 Y189.1346

G01 X-13.0542 Y192.6270

G03 X-14.0726 Y193.7409 I-1.1184 J0.0000

G02 X-26.8608 Y198.1152 I2.5399 J28.3051

G03 X-47.4844 Y198.1152 I-10.3118 J-16.0990

G02 X-60.2726 Y193.7409 I-15.3281 J23.9307

G03 X-61.2910 Y192.6270 I0.1000 J-1.1139

G01 X-61.2910 Y189.1346

G01 X-64.0542 Y189.1346

G01 X-64.0542 Y191.8978

G01 X-55.8274 Y191.8978

G02 X-54.5701 Y189.9433 I0.0000 J-1.3816

G40G01 X-37.1726 Y182.0162

M02

同时运行watch1.cam 和 watch2.cam,就可割具有拔模斜度的零件或模具型腔。

一个程序走X,Y,一个程序走U,V。但线切割机必须具有割斜度的功能。

线割锥齿轮也是一样的道理,只不过不是OFFSET齿形,而由模数决定上下齿形。Ms=Mb*(R-b)/R, Ms为小端模数,Mb为大端模数。R为锥距,b为齿宽。

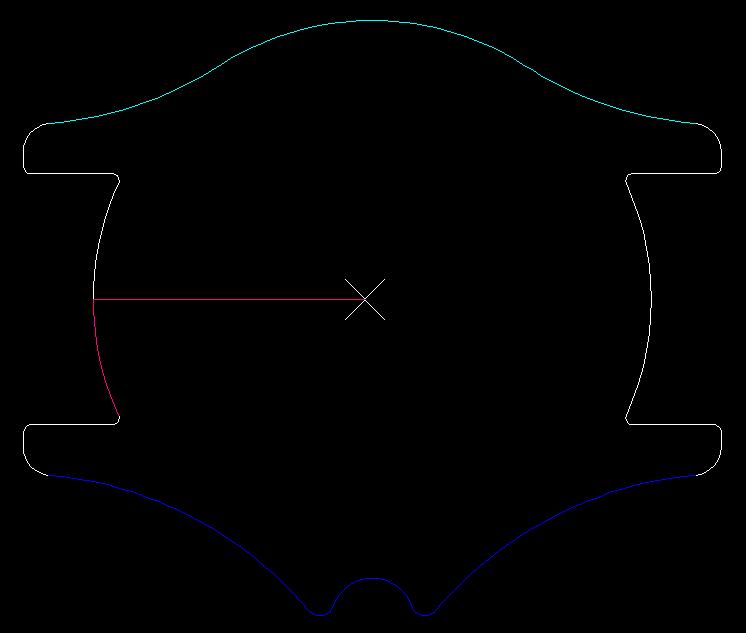

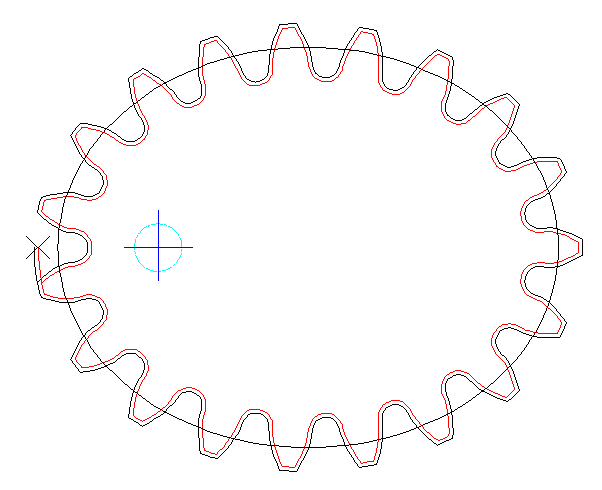

红色的是连为一体的PLINE,使工件逆时针切割

运行nc-l-arc-pl.vlx,选上图,得以下加工程序:

wire-watch

G90G17G40

G92G00 X2.7607 Y-115.3817

G01 X-16.7003 Y-115.3817

G03 X-14.9000 Y-123.6744 I20.0000 J0.0000

G02 X-15.3550 Y-124.3817 I-0.4550 J-0.2073

G01 X-21.2003 Y-124.3817

G03 X-21.7003 Y-124.8817 I0.0000 J-0.5000

G01 X-21.7003 Y-125.9924

G03 X-19.8790 Y-127.9844 I2.0000 J0.0000

G02 X-1.2448 Y-137.7116 I-2.4611 J-27.4270

G03 X0.4659 Y-137.3971 I0.7661 J0.6428

G02 X6.1336 Y-137.3971 I2.8338 J-0.9846

G03 X7.8442 Y-137.7116 I0.9446 J0.3282

G02 X26.4785 Y-127.9844 I21.0954 J-17.6998

G03 X28.2997 Y-125.9924 I-0.1787 J1.9920

G01 X28.2997 Y-124.8817

G03 X27.7997 Y-124.3817 I-0.5000 J0.0000

G01 X21.9545 Y-124.3817

G02 X21.4995 Y-123.6744 I0.0000 J0.5000

G03 X21.4995 Y-107.0890 I-18.1998 J8.2927

G02 X21.9545 Y-106.3817 I0.4550 J0.2073

G01 X27.7997 Y-106.3817

G03 X28.2997 Y-105.8817 I0.0000 J0.5000

G01 X28.2997 Y-104.7709

G03 X26.4785 Y-102.7789 I-2.0000 J0.0000

G02 X14.0870 Y-98.5402 I2.4611 J27.4270

G03 X-7.4876 Y-98.5402 I-10.7873 J-16.8414

G02 X-19.8790 Y-102.7789 I-14.8526 J23.1883

G03 X-21.7003 Y-104.7709 I0.1787 J-1.9920

G01 X-21.7003 Y-105.8817

G03 X-21.2003 Y-106.3817 I0.5000 J0.0000

G01 X-15.3550 Y-106.3817

G02 X-14.9000 Y-107.0890 I0.0000 J-0.5000

G03 X-16.7003 Y-115.3817 I18.1998 J-8.2927

G40G01 X2.7607 Y-115.3817

M02

红色的是连为一体的PLINE,使工件逆时针切割.

齿轮线切割演示程序:

Gearwiredemo.vlx----齿轮线切割演示程序,全自动地生成齿轮AutoCAD图及线切割G代码加工程序。

Igearwiredemo.vlx----内齿轮线切割演示程序,全自动地生成内齿轮AutoCAD图及线切割G代码加工程序。

3Bgearwiredemo.vlx----齿轮线切割演示程序,全自动地生成齿轮AutoCAD图并同时生成线切割G代码和3B代码加工程序。

3B igearwiredemo.vlx----内齿轮线切割演示程序,全自动地生成内齿轮AutoCAD图及线切割G代码和3B代码加工程序。

Cycloidwiredemo.vlx----摆线针轮线切割演示程序,全自动地生成摆线针轮行星AutoCAD图及线切割G代码和3B代码加工程序。

数控与线切割程序:

line插补:刀具走直线

ARC插补:刀具走圆弧

spline插补:刀具沿样条线前进.

mill-l-arc.vlx----数控铣(锣)程序,例如铣(锣)如下表壳外轮廓,轮廓是直线(line)和圆弧(arc)组成的轮廓:

X叉是一点,是AUTOCAD的point点,作为铣刀起点。封闭轮廓由直线(line)和圆弧(arc)组成。加载后,执行mill-l-arc命令,输入参数(文件名,落刀高度),选择所有的实体图形。选择时无须按顺序,只须框选所有的实体,或在select object提示下,输入all。然后自动生成如下数控加工程序,程序名:文件名.cam:

Owatch

G90G17G40

G92X0Y0Z0

S500M03

M08

G00 X-25.0000 Y25.6270

G04P1000

G00G42 X-25.0000 Y25.6270 Z-40.0000D1F50

G04P1000

G01 X-25.0000 Y9.5000

G03 X-24.5000 Y9.0000 I0.5000 J0.0000

G01 X-18.6548 Y9.0000

G02 X-18.1998 Y8.2927 I0.0000 J-0.5000

G03 X-18.1998 Y-8.2927 I18.1998 J-8.2927

G02 X-18.6548 Y-9.0000 I-0.4550 J-0.2073

G01 X-24.5000 Y-9.0000

G03 X-25.0000 Y-9.5000 I0.0000 J-0.5000

G01 X-25.0000 Y-10.6108

G03 X-23.1787 Y-12.6028 I2.0000 J0.0000

G02 X-4.5445 Y-22.3300 I-2.4611 J-27.4270

G03 X-2.8338 Y-22.0154 I0.7661 J0.6428

G02 X2.8338 Y-22.0154 I2.8338 J-0.9846

G03 X4.5445 Y-22.3300 I0.9446 J0.3282

G02 X23.1787 Y-12.6028 I21.0954 J-17.6998

G03 X25.0000 Y-10.6108 I-0.1787 J1.9920

G01 X25.0000 Y-9.5000

G03 X24.5000 Y-9.0000 I-0.5000 J0.0000

G01 X18.6548 Y-9.0000

G02 X18.1998 Y-8.2927 I0.0000 J0.5000

G03 X18.1998 Y8.2927 I-18.1998 J8.2927

G02 X18.6548 Y9.0000 I0.4550 J0.2073

G01 X24.5000 Y9.0000

G03 X25.0000 Y9.5000 I0.0000 J0.5000

G01 X25.0000 Y10.6108

G03 X23.1787 Y12.6028 I-2.0000 J0.0000

G02 X10.7873 Y16.8414 I2.4611 J27.4270

G03 X-10.7873 Y16.8414 I-10.7873 J-16.8414

G02 X-23.1787 Y12.6028 I-14.8526 J23.1883

G03 X-25.0000 Y10.6108 I0.1787 J-1.9920

G00 Z0

G40G00 X0Y0

M30

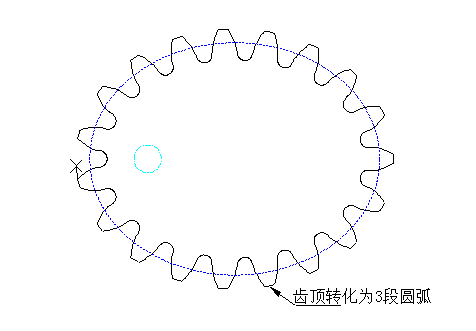

mill-l-arc-spline.vlx----数控铣(锣)程序,例如铣如上图的椭圆齿轮外轮廓,轮廓是直线(line)、圆弧(arc)和样条(spline)组成的轮廓。先用sp-to-arc.vlx把齿顶转化为圆弧(转化为3段圆弧就可),X叉是AUTOCAD的point点,作为铣刀起点(pdmode=3,pdsize=2).直线(line)、圆弧(arc)和样条(spline)插补。加载后,执行mill-l-arc-spline命令,输入参数(文件名,落刀高度,样条精度),选择所有的实体图形。选择时无须按顺序,只须框选所有的齿轮轮廓,包扩起始点。样条精度dt是spline转化为圆弧插补的步长。全长为1.0,dt为0.01时,样条转化为100段圆弧插补。dt越小,加工精度越高,程序越长 。以下为dt=0.1(齿廓样条转化为10段圆弧插补)时的齿轮加工程序,程序名:文件名.cam:

Oe1

G90G17G40

G92X0Y0Z0

S500M03

M08

G00 X-15.5759 Y-1.5463

G04P1000

G00G42 X-15.5759 Y-1.5463 Z-40.0000D1F50

G04P1000

G03 X-15.0759 Y-5.0392 I23.5352 J1.5869

G03 X-14.9284 Y-5.6670 I23.0066 J5.0735

G03 X-14.7640 Y-6.2900 I23.1037 J5.7628

G03 X-13.1760 Y-6.7337 I4.0450 J11.4139

G03 X-11.5393 Y-6.9269 I1.9033 J9.0964

G03 X-9.9096 Y-6.7293 I0.2328 J4.8996

G02 X-8.2983 Y-6.5016 I1.1920 J-2.6199

G02 X-7.0995 Y-7.5265 I-0.2798 J-1.5408

G02 X-7.1556 Y-9.1006 I-1.3698 J-0.7393

G02 X-8.4165 Y-10.2120 I-2.6321 J1.7154

G03 X-9.4247 Y-11.2303 I2.8328 J-3.8130

G03 X-10.3222 Y-12.6131 I8.4439 J-6.4629

G03 X-11.0304 Y-14.1026 I12.8144 J-7.0059

G03 X-10.6371 Y-14.6479 I22.6353 J15.9113

G03 X-10.2314 Y-15.1827 I22.5290 J16.6688

G03 X-9.8137 Y-15.7070 I22.3999 J17.4187

G03 X-8.2072 Y-15.4436 I-1.3324 J13.1568

G03 X-6.6519 Y-14.9649 I-2.3801 J10.4975

G03 X-5.2110 Y-14.2128 I-2.6048 J6.7469

G02 X-3.8252 Y-13.3849 I2.4961 J-2.6044

G02 X-2.3349 Y-13.8145 I0.3919 J-1.4403

G02 X-1.7628 Y-15.2582 I-0.9167 J-1.1984

G02 X-2.4517 Y-16.6954 I-3.0696 J0.5876

G03 X-3.0959 Y-18.1869 I5.7932 J-3.3873

G03 X-3.4760 Y-19.7697 I12.2300 J-3.7740

G03 X-3.6798 Y-21.3852 I16.6809 J-2.9246

G03 X-3.1038 Y-21.7830 I19.4555 J27.5542

G03 X-2.5205 Y-22.1684 I19.1762 J28.3913

G03 X-1.9302 Y-22.5413 I18.7859 J29.0755

G03 X-0.5253 Y-21.7332 I-6.9297 J13.6733

G03 X0.7773 Y-20.7693 I-6.9902 J10.8081

G03 X1.9247 Y-19.6265 I-6.0168 J7.1883

G02 X3.0003 Y-18.4273 I3.8480 J-2.3695

G02 X4.5398 Y-18.3757 I0.8110 J-1.2041

G02 X5.5014 Y-19.5812 I-0.4928 J-1.3793

G02 X5.2715 Y-21.1730 I-3.8270 J-0.2597

G03 X5.1165 Y-22.7849 I8.9743 J-1.6764

G03 X5.1851 Y-24.4041 I14.6882 J-0.1887

G03 X5.4113 Y-26.0092 I18.5449 J1.7952

G03 X6.0914 Y-26.2380 I12.8887 J37.1883

G03 X6.7750 Y-26.4543 I12.2885 J37.6618

G03 X7.4620 Y-26.6580 I11.6806 J38.1253

G03 X8.5722 Y-25.4811 I-12.1475 J12.5709

G03 X9.5585 Y-24.1989 I-11.1643 J9.6078

G03 X10.3738 Y-22.8026 I-8.9099 J6.1389

G02 X11.1113 Y-21.3722 I4.8495 J-1.5951

G02 X12.5816 Y-20.9284 I1.0846 J-0.9359

G02 X13.8061 Y-21.8566 I-0.1221 J-1.4328

G02 X13.9919 Y-23.4542 I-4.4806 J-1.3308

G03 X14.2581 Y-25.0491 I10.6848 J0.9637

G03 X14.7193 Y-26.5997 I15.1995 J3.6772

G03 X15.3230 Y-28.1008 I18.0374 J6.3823

G03 X16.0453 Y-28.1565 I3.6084 J42.0751

G03 X16.7684 Y-28.1998 I2.8896 J42.1820

G03 X17.4920 Y-28.2307 I2.1689 J42.2702

G03 X18.2712 Y-26.8134 I-16.1397 J9.7963

G03 X18.9141 Y-25.3295 I-14.0161 J6.9538

G03 X19.3718 Y-23.7793 I-10.3774 J3.9068

G02 X19.7492 Y-22.2156 I4.9722 J-0.3727

G02 X21.0733 Y-21.4385 I1.2737 J-0.6538

G02 X22.4792 Y-22.0548 I0.2186 J-1.4131

G02 X23.0399 Y-23.5628 I-4.4796 J-2.5238

G03 X23.6800 Y-25.0471 I10.5023 J3.6489

G03 X24.4976 Y-26.4424 I13.6210 J7.0439

G03 X25.4455 Y-27.7528 I15.2972 J10.0683

G03 X26.1576 Y-27.6354 I-6.3976 J41.0251

G03 X26.8678 Y-27.5056 I-7.0770 J40.7202

G03 X27.5758 Y-27.3633 I-7.7505 J40.3992

G03 X27.9960 Y-25.7996 I-18.1707 J5.7205

G03 X28.2666 Y-24.2034 I-14.9386 J3.3540

G03 X28.3295 Y-22.5868 I-9.9888 J1.1982

G02 X28.3134 Y-20.9785 I4.1842 J0.8460

G02 X29.4183 Y-19.9075 I1.4070 J-0.3461

G02 X30.9343 Y-20.1641 I0.5549 J-1.3285

G02 X31.8435 Y-21.4929 I-3.5200 J-3.3835

G03 X32.8280 Y-22.7769 I8.5782 J5.5585

G03 X33.9768 Y-23.9173 I10.3387 J9.2652

G03 X35.2409 Y-24.9290 I10.9016 J12.3266

G03 X35.8879 Y-24.6397 I-14.9539 J34.3154

G03 X36.5299 Y-24.3378 I-15.4519 J33.7009

G03 X37.1666 Y-24.0234 I-15.9409 J33.0815

G03 X37.1859 Y-22.4000 I-17.8793 J1.0244

G03 X37.0385 Y-20.7836 I-13.8218 J-0.4453

G03 X36.6486 Y-19.2100 I-7.9213 J-1.1276

G02 X36.1923 Y-17.6678 I2.9751 J1.7189

G02 X36.9812 Y-16.3377 I1.4852 J0.0181

G02 X38.5157 Y-16.1635 I0.9082 J-1.1545

G02 X39.7511 Y-17.1989 I-1.9533 J-3.5853

G03 X41.0525 Y-18.1662 I5.6094 J6.1878

G03 X42.4940 Y-18.9115 I6.1250 J10.0802

G03 X44.0176 Y-19.4712 I5.6549 J13.0384

G03 X44.5321 Y-19.0187 I-20.4787 J23.8021

G03 X45.0372 Y-18.5544 I-20.7169 J23.0423

G03 X45.5325 Y-18.0782 I-20.9381 J22.2759

G03 X45.0859 Y-16.5017 I-15.3991 J-3.5107

G03 X44.4538 Y-14.9906 I-11.0714 J-3.7438

G03 X43.6476 Y-13.7471 I-5.5319 J-2.7033

G02 X42.6357 Y-12.3967 I1.9110 J2.4865

G02 X42.9208 Y-10.8592 I1.4379 J0.5285

G02 X44.3063 Y-10.1341 I1.3007 J-0.7992

G02 X45.8263 Y-10.6957 I-0.2928 J-3.1304

G03 X47.3835 Y-11.1912 I2.6039 J5.4880

G03 X49.0128 Y-11.3547 I1.7987 J9.7254

G03 X50.6491 Y-11.2777 I0.2326 J12.4845

G03 X50.9490 Y-10.6948 I-22.5643 J11.9781

G03 X51.2342 Y-10.1035 I-22.7351 J11.3309

G03 X51.5044 Y-9.5042 I-22.8705 J10.6697

G03 X50.5260 Y-8.1678 I-11.3690 J-7.2968

G03 X49.3671 Y-6.9858 I-7.5368 J-6.2301

G03 X48.1376 Y-6.2155 I-2.6287 J-2.8298

G02 X46.6936 Y-5.4075 I0.7357 J3.0089

G02 X46.2981 Y-3.8747 I1.1206 J1.1066

G02 X47.2458 Y-2.6036 I1.5782 J-0.1879

G02 X48.9009 Y-2.4661 I1.0549 J-2.6685

G03 X50.4843 Y-2.3236 I0.4345 J4.0412

G03 X52.0407 Y-1.7608 I-2.2912 J8.7682

G03 X53.4907 Y-0.9607 I-5.1384 J11.0256

G03 X53.5083 Y-0.3203 I-23.1676 J0.9603

G03 X53.5083 Y0.3203 I-23.1921 J0.3203

G03 X53.4907 Y0.9607 I-23.2192 J-0.3209

G03 X52.0407 Y1.7608 I-6.5883 J-10.2255

G03 X50.4843 Y2.3236 I-3.8476 J-8.2053

G03 X48.9009 Y2.4661 I-1.1489 J-3.8987

G02 X47.2458 Y2.6036 I-0.6002 J2.8060

G02 X46.2981 Y3.8747 I0.6305 J1.4590

G02 X46.6936 Y5.4075 I1.5161 J0.4262

G02 X48.1376 Y6.2155 I2.1797 J-2.2009

G03 X49.3671 Y6.9858 I-1.3991 J3.6001

G03 X50.5260 Y8.1678 I-6.3779 J7.4121

G03 X51.5044 Y9.5042 I-10.3906 J8.6332

G03 X51.2342 Y10.1035 I-23.1406 J-10.0704

G03 X50.9490 Y10.6948 I-23.0203 J-10.7396

G03 X50.6491 Y11.2777 I-22.8642 J-11.3952

G03 X49.0128 Y11.3547 I-1.4037 J-12.4076

G03 X47.3835 Y11.1912 I0.1694 J-9.8889

G03 X45.8263 Y10.6957 I1.0467 J-5.9835

G02 X44.3063 Y10.1341 I-1.8128 J2.5688

G02 X42.9208 Y10.8592 I-0.0848 J1.5242

G02 X42.6357 Y12.3967 I1.1527 J1.0090

G02 X43.6476 Y13.7471 I2.9230 J-1.1361

G03 X44.4538 Y14.9906 I-4.7257 J3.9468

G03 X45.0859 Y16.5017 I-10.4393 J5.2549

G03 X45.5325 Y18.0782 I-14.9525 J5.0873

G03 X45.0372 Y18.5544 I-21.4334 J-21.7997

G03 X44.5321 Y19.0187 I-21.2220 J-22.5779

G03 X44.0176 Y19.4712 I-20.9932 J-23.3496

G03 X42.4940 Y18.9115 I4.1313 J-13.5982

G03 X41.0525 Y18.1662 I4.6835 J-10.8254

G03 X39.7511 Y17.1989 I4.3081 J-7.1551

G02 X38.5157 Y16.1635 I-3.1887 J2.5500

G02 X36.9812 Y16.3377 I-0.6263 J1.3287

G02 X36.1923 Y17.6678 I0.6964 J1.3120

G02 X36.6486 Y19.2100 I3.4314 J-0.1767

G03 X37.0385 Y20.7836 I-7.5314 J2.7012

G03 X37.1859 Y22.4000 I-13.6744 J2.0617

G03 X37.1666 Y24.0234 I-17.8986 J0.5990

G03 X36.5299 Y24.3378 I-16.5776 J-32.7671

G03 X35.8879 Y24.6397 I-16.0939 J-33.3991

G03 X35.2409 Y24.9290 I-15.6010 J-34.0261

G03 X33.9768 Y23.9173 I9.6375 J-13.3382

G03 X32.8280 Y22.7769 I9.1900 J-10.4057

G03 X31.8435 Y21.4929 I7.5936 J-6.8425

G02 X30.9343 Y20.1641 I-4.4291 J2.0547

G02 X29.4183 Y19.9075 I-0.9612 J1.0719

G02 X28.3134 Y20.9785 I0.3021 J1.4171

G02 X28.3295 Y22.5868 I4.2002 J0.7623

G03 X28.2666 Y24.2034 I-10.0517 J0.4184

G03 X27.9960 Y25.7996 I-15.2092 J-1.7579

G03 X27.5758 Y27.3633 I-18.5909 J-4.1567

G03 X26.8678 Y27.5056 I-8.4586 J-40.2569

G03 X26.1576 Y27.6354 I-7.7872 J-40.5903

G03 X25.4455 Y27.7528 I-7.1097 J-40.9078

G03 X24.4976 Y26.4424 I14.3492 J-11.3787

G03 X23.6800 Y25.0471 I12.8035 J-8.4392

G03 X23.0399 Y23.5628 I9.8622 J-5.1332

G02 X22.4792 Y22.0548 I-5.0403 J1.0158

G02 X21.0733 Y21.4385 I-1.1873 J0.7968

G02 X19.7492 Y22.2156 I-0.0503 J1.4308

G02 X19.3718 Y23.7793 I4.5948 J1.9364

G03 X18.9141 Y25.3295 I-10.8351 J-2.3565

G03 X18.2712 Y26.8134 I-14.6590 J-5.4699

G03 X17.4920 Y28.2307 I-16.9189 J-8.3790

G03 X16.7684 Y28.1998 I1.4453 J-42.3011

G03 X16.0453 Y28.1565 I2.1666 J-42.2253

G03 X15.3230 Y28.1008 I2.8861 J-42.1309

G03 X14.7193 Y26.5997 I17.4337 J-7.8834

G03 X14.2581 Y25.0491 I14.7383 J-5.2278

G03 X13.9919 Y23.4542 I10.4186 J-2.5586

G02 X13.8061 Y21.8566 I-4.6664 J-0.2669

G02 X12.5816 Y20.9284 I-1.3465 J0.5046

G02 X11.1113 Y21.3722 I-0.3857 J1.3797

G02 X10.3738 Y22.8026 I4.1120 J3.0255

G03 X9.5585 Y24.1989 I-9.7253 J-4.7425

G03 X8.5722 Y25.4811 I-12.1506 J-8.3255

G03 X7.4620 Y26.6580 I-13.2577 J-11.3940

G03 X6.7750 Y26.4543 I10.9936 J-38.3290

G03 X6.0914 Y26.2380 I11.6048 J-37.8780

G03 X5.4113 Y26.0092 I12.2086 J-37.4171

G03 X5.1851 Y24.4041 I18.3187 J-3.4003

G03 X5.1165 Y22.7849 I14.6196 J-1.4305

G03 X5.2715 Y21.1730 I9.1293 J0.0645

G02 X5.5014 Y19.5812 I-3.5971 J-1.3321

G02 X4.5398 Y18.3757 I-1.4543 J0.1738

G02 X3.0003 Y18.4273 I-0.7285 J1.2557

G02 X1.9247 Y19.6265 I2.7724 J3.5687

G03 X0.7773 Y20.7693 I-7.1643 J-6.0455

G03 X-0.5253 Y21.7332 I-8.2928 J-9.8442

G03 X-1.9302 Y22.5413 I-8.3346 J-12.8652

G03 X-2.5205 Y22.1684 I18.1957 J-29.4485

G03 X-3.1038 Y21.7830 I18.5929 J-28.7767

G03 X-3.6798 Y21.3852 I18.8795 J-27.9520

G03 X-3.4760 Y19.7697 I16.8847 J1.3091

G03 X-3.0959 Y18.1869 I12.6101 J2.1912

G03 X-2.4517 Y16.6954 I6.4374 J1.8958

G02 X-1.7628 Y15.2582 I-2.3807 J-2.0248

G02 X-2.3349 Y13.8145 I-1.4887 J-0.2453

G02 X-3.8252 Y13.3849 I-1.0985 J1.0106

G02 X-5.2110 Y14.2128 I1.1104 J3.4322

G03 X-6.6519 Y14.9649 I-4.0457 J-5.9948

G03 X-8.2072 Y15.4436 I-3.9355 J-10.0188

G03 X-9.8137 Y15.7070 I-2.9389 J-12.8934

G03 X-10.2314 Y15.1827 I21.9821 J-17.9430

G03 X-10.6371 Y14.6479 I22.1233 J-17.2037

G03 X-11.0304 Y14.1026 I22.2421 J-16.4565

G03 X-10.3222 Y12.6131 I13.5226 J5.5163

G03 X-9.4247 Y11.2303 I9.3414 J5.0800

G03 X-8.4165 Y10.2120 I3.8411 J2.7947

G02 X-7.1556 Y9.1006 I-1.3711 J-2.8267

G02 X-7.0995 Y7.5265 I-1.3138 J-0.8348

G02 X-8.2983 Y6.5016 I-1.4786 J0.5158

G02 X-9.9096 Y6.7293 I-0.4193 J2.8476

G03 X-11.5393 Y6.9269 I-1.3970 J-4.7020

G03 X-13.1760 Y6.7337 I0.2667 J-9.2896

G03 X-14.7641 Y6.2900 I2.4570 J-11.8576

G03 X-14.9284 Y5.6668 I22.8305 J-6.3532

G03 X-15.0758 Y5.0388 I22.9827 J-5.7268

G03 X-15.2062 Y4.4065 I23.1270 J-5.0981

G03 X-13.9692 Y3.3001 I9.0353 J8.8573

G03 X-12.5789 Y2.3959 I5.7057 J7.2515

G03 X-11.1244 Y1.9193 I1.8388 J3.1544

G02 X-9.5583 Y1.4324 I-0.0657 J-2.9734

G02 X-8.8746 Y-0.0002 I-0.8957 J-1.3069

G02 X-9.5584 Y-1.4328 I-1.5794 J-0.1256

G02 X-11.1246 Y-1.9196 I-1.6317 J2.4868

G03 X-12.5790 Y-2.3963 I0.3848 J-3.6317

G03 X-13.9693 Y-3.3006 I4.3159 J-8.1560

G03 X-15.2063 Y-4.4070 I7.7988 J-9.9637

G00 Z0

G40G00 X0Y0

M30

如果要提高加工精度,把dt设置小一些。例如dt=0.01, 齿廓样条转化为100段圆弧插补。

如果要给0.05的右补偿,可用sp-or-ellipse-to-arc.vlx把先把齿廓样条转化为圆弧, 根据需要取精度,例如,取0.02,再用l-arc-to-pl.vlx把齿廓转化为多段线pline.

未连接的地方需用fillet倒圆角,圆角半径为0,使它们连成一体的多段线pline。再offset,偏距0.05,得到一补偿路径(红色的路径)。

端点未连接,须延长使之相连,起始点需移至补偿的新路径端点。

再加载mill-l-arc-pl.vlx,键入mill-l-arc-pl命令,选取端点和红色的新路径,就得到右补偿为0.05的新加工程序:mill-ebu05.cam。也可用explode命令将多段线pline转化为直线line和圆弧arc,再转数控线切割加工程序。

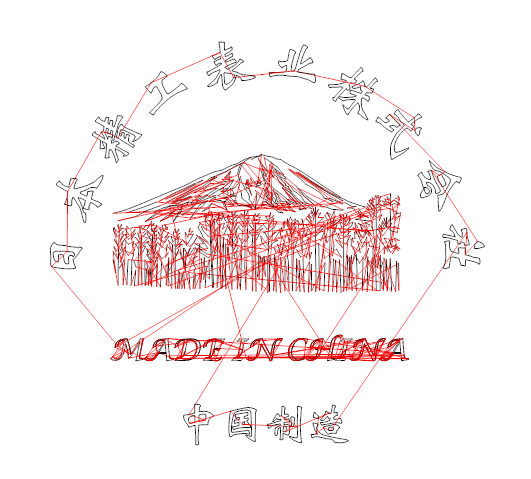

Mill-cut.vlx----数控铣(锣)程序,例如,在铜公(电火花的铜电极)上铣如下表壳底部图案:

图案可由点(point) 、直线(line)、圆(circle) 、圆弧(arc) 、样条(spline)和多段线(pline)、椭圆或椭圆弧(ellipse)组成。加载后,执行mill-sp-pl命令,输入参数(文件名,落刀高度,提刀高度,样条精度),选择所有的实体图形。选择时无须按顺序,只须框选所有的实体,或在select object提示下,输入all。可得到如下加工程序(落刀高度-40.0, 提刀高度-38.0,dt=0.1):

%

Ofujimountain

G90G17G40

S1000M03

M08

G00 X1533.2077 Y-2149.5091

G01 Z-40.0000

G03 X1601.0570 Y-2153.3745 I41.8446 J137.0846

G00 Z-38.0000

G00 X1526.4331 Y-2086.9563

G01 Z-40.0000

G03 X1533.2077 Y-2149.5091 I59.1048 J-25.2421

G00 Z-38.0000

G00 X1539.0892 Y-2021.2911

G01 Z-40.0000

G03 X1526.4331 Y-2086.9563 I2890.9921 J-591.2528

G00 Z-38.0000

G00 X1539.0892 Y-2021.2911

G01 Z-40.0000

G03 X1552.3521 Y-1955.7443 I-41041.3439 J8338.5143

G00 Z-38.0000

G00 X1565.7886 Y-1890.2330

G01 Z-40.0000

G03 X1552.3521 Y-1955.7443 I7719.2804 J-1617.3702

G00 Z-38.0000

G00 X1580.2149 Y-1824.9337

G01 Z-40.0000

G03 X1565.7886 Y-1890.2330 I3001.5737 J-697.3665

G00 Z-38.0000

G00 X1595.8067 Y-1759.9017

G01 Z-40.0000

G03 X1580.2149 Y-1824.9337 I7176.1291 J-1754.9099

G00 Z-38.0000

G00 X1618.4258 Y-1697.3403

G01 Z-40.0000

G03 X1595.8067 Y-1759.9017 I170.3036 J-96.9428

G00 Z-38.0000

G00 X1673.8039 Y-1665.0820

G01 Z-40.0000

G03 X1618.4258 Y-1697.3403 I1.3991 J-66.0651

G00 Z-38.0000

G00 X1732.9654 Y-1693.0111

G01 Z-40.0000

G03 X1673.8039 Y-1665.0820 I-67.5637 J-66.4937

G00 Z-38.0000

G00 X1760.6853 Y-1646.2107

G01 Z-40.0000

。。。。。。

G00 Z-38.0000

G00 X-2956.4467 Y-2058.8422

G01 Z-40.0000

G03 X-2973.0220 Y-1965.5696 I-1134.1083 J-153.4319

G00 Z-38.0000

G00 X-2951.2123 Y-2141.6544

G01 Z-40.0000

G03 X-2956.4467 Y-2058.8422 I-581.9658 J4.7870

G00 Z-38.0000

G00 X-3041.0683 Y-1979.5169

G01 Z-40.0000

G01 X-3011.4071 Y-1830.4550

G00 Z-38.0000

G00 X-3339.4253 Y-2159.9602

G01 Z-40.0000

G03 X-3291.4439 Y-2186.1114 I99.3844 J125.2544

G00 Z-38.0000

G00 X-3291.4439 Y-2186.1114

G01 Z-40.0000

G03 X-3218.1633 Y-2192.2134 I48.8838 J143.9852

G00 Z-38.0000

G00 X-3218.1633 Y-2192.2134

G01 Z-40.0000

G03 X-3158.8409 Y-2173.9075 I-36.1607 J222.4572

G00 Z-38.0000

G00 X-3158.8409 Y-2173.9075

G01 Z-40.0000

G03 X-3130.9244 Y-2153.8583 I-39.5066 J84.4687

G00 Z-38.0000

G00 X-3130.9244 Y-2153.8583

G01 Z-40.0000

G03 X-3100.3908 Y-2119.8617 I-535.8342 J511.9631

G00 Z-38.0000

G00 X-3100.3908 Y-2119.8617

G01 Z-40.0000

G03 X-3063.7504 Y-2053.6120 I-148.7259 J125.5121

G00 Z-38.0000

G00 X-3063.7504 Y-2053.6120

G01 Z-40.0000

G03 X-3041.0683 Y-1979.5169 I-2983.2353 J953.7522

G00 Z-38.0000

G00 X-3294.9335 Y-2113.7597

G01 Z-40.0000

G01 X-3339.4253 Y-2159.0885

G00 Z-38.0000

G00 X-3041.9407 Y-1752.8731

G01 Z-40.0000

G01 X-3103.8803 Y-2057.9705

G00 Z-38.0000

G00 X-3145.7550 Y-2139.0392

G01 Z-40.0000

G03 X-3103.8803 Y-2057.9705 I-121.9095 J114.3195

G00 Z-38.0000

G00 X-3204.2051 Y-2165.1905

G01 Z-40.0000

G03 X-3145.7550 Y-2139.0392 I-1.9782 J82.8172

G00 Z-38.0000

G00 X-3258.2931 Y-2152.1148

G01 Z-40.0000

G03 X-3204.2051 Y-2165.1905 I51.5141 J94.6841

G00 Z-38.0000

G00 X-3294.9335 Y-2113.7597

G01 Z-40.0000

G03 X-3258.2931 Y-2152.1148 I78.1918 J38.0174

G00 Z-38.0000

G00 Z0

G40G00 X0 Y0

M30

加工程序太长,中间部分被删除。完整程序在wfujimountain.cam文件中。

如果嫌加工程序太长,可把加工程序分成几段。例如,把加工程序分成3段:“日本精工表业株式会社”为一段,“富士山和森林”为一段,“MADE IN CHINA和中国制造”为一段。在运行Mill-cut命令后,选择各自的实体图形。例如,“富士山和森林”的加工程序,只须选“富士山和森林”实体图形,然后自动生成“富士山和森林”的加工程序,程序名:文件名.cam。

Check.vlx----反向检查程序。加载后执行Check命令,可由数控与线切割程序反向画出AUTOCAD图及刀具轨迹。例如,上面很长的表客底部的程序名为:wfujimountain.cam,执行Check命令后,点wfujimountain.cam后生成如下图形:

红色线为刀具轨迹。

Erase-by-color.VLX----按颜色删除程序。加载后执行erase-by- color命令。输入颜色名,即可自动删除某种颜色的实体图形。例如删除上图中红色的刀具轨迹,只需输入颜色号1。 在AUTOCAD中,整数1是红色的代号。删除上图中红色的刀具轨迹或关闭G00图层后,得到如下图形:

可以看出,由数控与线切割程序反向画出的AUTOCAD图和原图完全一样。这证明加工程序正确无误。

Erase-by-layer.VLX----按图层删除程序。加载后执行erase-by-layer命令。输入图层名,即可自动删除图层上的所以实体图形。

erase-by-entsort.VLX----按实体名删除程序。加载后执行erase-by- entsort命令。输入实体名,即可自动删除某种实体图形。例如删除齿轮图中所有的SPLINE样条线。

线切割程序:

试用程序:nc-l-arc.vlx

nc-l-arc.vlx----线切割试用程序,例如线切割如下表壳外轮廓的模具内腔,轮廓是直线(line)和圆弧(arc)组成的封闭轮廓。

X叉是AUTOCAD的point点,作为线切割起点,穿丝孔。封闭轮廓由直线(line)和圆弧(arc)组成。加载后,执行nc-l-arc命令,只需输入文件名,选择所有的实体图形。选择时无须按顺序,只须框选所有的实体,或在select object提示下,输入all。然后自动生成如下线切割加工程序:

wwatch

G90G17G40

G92 X0.0000 Y0.0000

G01 X-15.9091 Y12.1202

G03 X-18.1998 Y-8.2927 I15.9091 J-12.1202

G02 X-18.6548 Y-9.0000 I-0.4550 J-0.2073

G01 X-24.5000 Y-9.0000

G03 X-25.0000 Y-9.5000 I0.0000 J-0.5000

G01 X-25.0000 Y-10.6108

G03 X-23.1787 Y-12.6028 I2.0000 J0.0000

G02 X-4.5445 Y-22.3300 I-2.4611 J-27.4270

G03 X-2.8338 Y-22.0154 I0.7661 J0.6428

G02 X2.8338 Y-22.0154 I2.8338 J-0.9846

G03 X4.5445 Y-22.3300 I0.9446 J0.3282

G02 X23.1787 Y-12.6028 I21.0954 J-17.6998

G03 X25.0000 Y-10.6108 I-0.1787 J1.9920

G01 X25.0000 Y-9.5000

G03 X24.5000 Y-9.0000 I-0.5000 J0.0000

G01 X18.6548 Y-9.0000

G02 X18.1998 Y-8.2927 I0.0000 J0.5000

G03 X18.1998 Y8.2927 I-18.1998 J8.2927

G02 X18.6548 Y9.0000 I0.4550 J0.2073

G01 X24.5000 Y9.0000

G03 X25.0000 Y9.5000 I0.0000 J0.5000

G01 X25.0000 Y10.6108

G03 X23.1787 Y12.6028 I-2.0000 J0.0000

G02 X10.7873 Y16.8414 I2.4611 J27.4270

G03 X-10.7873 Y16.8414 I-10.7873 J-16.8414

G02 X-23.1787 Y12.6028 I-14.8526 J23.1883

G03 X-25.0000 Y10.6108 I0.1787 J-1.9920

G01 X-25.0000 Y9.5000

G03 X-24.5000 Y9.0000 I0.5000 J0.0000

G01 X-18.6548 Y9.0000

G02 X-18.1998 Y8.2927 I0.0000 J-0.5000

G40G01 X0.0000 Y0.0000

M02

wire-l-arc-sp.vlx----线切割程序。例如,线切割如下齿轮部分齿的外轮廓,轮廓是由直线(line)、圆弧(arc) 和样条(spline)组成的不封闭轮廓。

X叉是AUTOCAD的point点,作为线切割起点,穿丝孔。不封闭轮廓由直线(line)、圆弧(arc) 和样条(spline)组成。加载后,执行wire-l-arc-sp命令后,只需输入文件名和样条精度dt=0.1,然后选择所有的实体图形。选择时无须按顺序,只须框选所有的实体,或在select object提示下,输入all。然后自动生成如下线切割加工程序:

wire-geartooth

G90G17G40

G92G00 X-26.6140 Y0.0000

G01 X-19.6501 Y0.0000

G03 X-19.2761 Y-3.8153 I19.6501 J0.0000

G02 X-19.3783 Y-4.6066 I-1.2583 J-0.2398

G02 X-19.9073 Y-5.2090 I-1.3682 J0.6680

G02 X-20.6393 Y-5.5534 I-1.7012 J2.6657

G03 X-21.3494 Y-5.9439 I2.0675 J-4.6009

G03 X-22.0043 Y-6.4221 I4.2584 J-6.5195

G03 X-22.6121 Y-6.9590 I6.1485 J-7.5738

G03 X-23.1770 Y-7.5410 I7.8810 J-8.2137

G03 X-23.7016 Y-8.1597 I9.4986 J-8.5859

G03 X-24.1879 Y-8.8089 I11.0223 J-8.7633

G03 X-24.6376 Y-9.4841 I12.4646 J-8.7893

G03 X-24.0573 Y-10.8724 I24.6376 J9.4841

G03 X-23.2609 Y-11.0266 I3.2971 J14.8912

G03 X-22.4572 Y-11.1365 I2.3097 J13.8907

G03 X-21.6484 Y-11.1978 I1.3707 J12.7304

G03 X-20.8373 Y-11.2046 I0.5015 J11.3721

G03 X-20.0281 Y-11.1492 I-0.2619 J9.7518

G03 X-19.2278 Y-11.0190 I-0.8481 J7.7407

G03 X-18.4510 Y-10.7879 I-1.0453 J4.9346

G02 X-17.6917 Y-10.5089 I1.4615 J-2.8043

G02 X-16.8914 Y-10.5556 I0.3147 J-1.4897

G02 X-16.2564 Y-11.0387 I-0.4197 J-1.2103

G03 X-16.0578 Y-11.3258 I16.2564 J11.0387

G02 X-15.8292 Y-12.0902 I-1.0520 J-0.7308

G02 X-16.0675 Y-12.8557 I-1.5216 J0.0538

G02 X-16.5961 Y-13.4680 I-2.6384 J1.7433

G03 X-17.0860 Y-14.1136 I3.7601 J-3.3621

G03 X-17.4898 Y-14.8168 I6.5419 J-4.2238

G03 X-17.8267 Y-15.5545 I8.6975 J-4.4182

G03 X-18.1061 Y-16.3160 I10.5405 J-4.2982

G03 X-18.3337 Y-17.0946 I12.1696 J-3.9802

G03 X-18.5139 Y-17.8855 I13.6337 J-3.5225

G03 X-18.6501 Y-18.6852 I14.9619 J-2.9596

G03 X-17.5552 Y-19.7174 I18.6501 J18.6852

G03 X-16.7650 Y-19.5343 I-3.0447 J14.9448

G03 X-15.9860 Y-19.3079 I-3.5398 J13.6292

G03 X-15.2222 Y-19.0349 I-3.9257 J12.1873

G03 X-14.4785 Y-18.7112 I-4.1673 J10.5929

G03 X-13.7618 Y-18.3315 I-4.2057 J8.8022

G03 X-13.0836 Y-17.8870 I-3.9232 J6.7265

G03 X-12.4680 Y-17.3600 I-2.9620 J4.0828

G02 X-11.8878 Y-16.7962 I2.4757 J-1.9674

G02 X-11.1377 Y-16.5133 I0.8934 J-1.2329

G02 X-10.3612 Y-16.6964 I0.1089 J-1.2763

G03 X-10.0629 Y-16.8779 I10.3612 J16.6964

G02 X-9.5432 Y-17.4833 I-0.6638 J-1.0956

G02 X-9.4495 Y-18.2795 I-1.4119 J-0.5698

G02 X-9.6834 Y-19.0539 I-3.1193 J0.5195

G03 X-9.8684 Y-19.8429 I4.8026 J-1.5421

G03 X-9.9512 Y-20.6496 I7.6943 J-1.1978

G03 X-9.9589 Y-21.4606 I9.7426 J-0.4986

G03 X-9.9044 Y-22.2698 I11.3774 J0.3606

G03 X-9.7956 Y-23.0737 I12.7364 J1.3137

G03 X-9.6386 Y-23.8695 I13.8877 J2.3274

G03 X-9.4378 Y-24.6554 I14.8722 J3.3818

G03 X-8.0177 Y-25.1531 I9.4378 J24.6554

G03 X-7.3702 Y-24.6644 I-8.8601 J12.4144

G03 X-6.7507 Y-24.1407 I-8.7773 J11.0111

G03 X-6.1640 Y-23.5807 I-8.5433 J9.5369

G03 X-5.6162 Y-22.9825 I-8.1155 J7.9821

G03 X-5.1160 Y-22.3441 I-7.4223 J6.3306

G03 X-4.6772 Y-21.6622 I-6.3199 J4.5493

G03 X-4.3292 Y-20.9303 I-4.3665 J2.5251

G02 X-4.0284 Y-20.1793 I3.0619 J-0.7904

G02 X-3.4582 Y-19.6158 I1.3176 J-0.7630

G02 X-2.6743 Y-19.4672 I0.6186 J-1.1217

G03 X0.0000 Y-19.6501 I2.6743 J19.4672

G01 X0.0000 Y-26.2134

G40G01 X-26.6140 Y0.0000

M02

gearwire.vlx----外齿轮线切割程序,全自动地生成外齿轮AutoCAD图及线切割G代码加工程序。

igearwire.vlx----内齿轮线切割程序,全自动地生成内齿轮AutoCAD图及线切割G代码加工程序。

3Bgearwire.vlx----外齿轮线切割程序,全自动地生成外齿轮AutoCAD图及线切割G代码和3B代码加工程序。

3Bigearwire.vlx----内齿轮线切割程序,全自动地生成内齿轮AutoCAD图及线切割G代码和3B代码加工程序。

Cycloidwire.vlx----摆线针轮线切割程序,全自动地生成摆线针轮行星AutoCAD图及线切割G代码和3B代码加工程序。

3Bwire-l-arc.vlx----线切割快走丝程序,用法同wire-l-arc.vlx,同时生成线切割G代码和3B代码加工程序。割line和arc,同时生成线切割慢走丝G代码和快走丝3B代码加工程序。

3Bwire-l-arc-pl.vlx----线切割快走丝程序,用法同wire-l-arc-pl.vlx,同时生成线切割G代码和3B代码加工程序。割line,arc和pline,同时生成线切割慢走丝G代码和快走丝3B代码加工程序。

3Bwire-l-arc-pl-sp-el.vlx----线切割快走丝程序,用法同wire-l-arc-pl-sp-el.vlx,同时生成线切割G代码和3B代码加工程序。割line,arc,pline,spline和ellipse,同时生成线切割慢走丝G代码和快走丝3B代码加工程序。

3Bwire-l-arc-sp-el.vlx----线切割快走丝程序,用法同wire-l-arc-sp-el.vlx,同时生成线切割G代码和3B代码加工程序。割line,arc,spline和ellipse,同时生成线切割慢走丝G代码和快走丝3B代码加工程序。

Wire-circle.vlx ----线切割程序,慢走丝割圆, 生成线切割慢走丝G代码.

3bwire-circle.vlx ----线切割程序,快走丝割圆,同时生成线切割慢走丝G代码和快走丝3B代码加工程序。

Lenth.vlx----计算走丝切割工件的轨迹长度

Check.vlx----由G代码加工程序画出DWG图

Check3B.vlx----由3B代码加工程序画出DWG图;并计算出走丝切割工件的轨迹长度.

Sp-or-ellipse-to-arc.vlx----样条或椭圆(弧)转化为圆弧

Sp-to-line.vlx----样条转化为直线

L-arc-to-pl.vlx----直线和圆弧转化为多段线pline(或者pedit的join连接命令)

Explode----多段线pline转化为直线和圆弧的命令

crec.vlx----矩形程序,输入矩形中心点,长度和宽度。AutoCAD缺少一个以矩形中心点定位画矩形的命令,这个矩形程序填补此缺陷。

ncpassword.vlx----注册命令.加载后,执行ncpassword命令(在AutoCAD的命令Command:下,输入ncpassword命令). 要获取注册码,请把你的电脑的机器码.

在执行ncpassword命令后,在text窗口上打印出机器码:

~~~~~~~~~~~~~~~~~~~~~~~齿轮线切割演示程序

Gearwiredemo.vlx----齿轮线切割演示程序,全自动地生成齿轮AutoCAD图及线切割G代码加工程序。

3Bgearwiredemo.vlx----齿轮线切割演示程序,全自动地生成齿轮AutoCAD图并同时生成线切割G代码和3B代码加工程序。

Igearwiredemo.vlx----内齿轮线切割演示程序,全自动地生成内齿轮AutoCAD图及线切割G代码加工程序。

3B igearwiredemo.vlx----内齿轮线切割演示程序,全自动地生成内齿轮AutoCAD图及线切割G代码和3B代码加工程序。

Cycloidwiredemo.vlx----摆线针轮线切割演示程序,全自动地生成摆线针轮行星AutoCAD图及线切割G代码和3B代码加工程序。

Start point = 0.0000 , 0.0000 ; x , y

XYR格式:

wire-watch

G90G17G40

G92G00 X-25.0000 Y25.6270

G01 X-25.0000 Y9.5000

G03 X-24.5000 Y9.0000 R0.5000

G01 X-18.6548 Y9.0000

G02 X-18.1998 Y8.2927 R0.5000

G03 X-18.1998 Y-8.2927 R20.0000

G02 X-18.6548 Y-9.0000 R0.5000

G01 X-24.5000 Y-9.0000

G03 X-25.0000 Y-9.5000 R0.5000

G01 X-25.0000 Y-10.6108

G03 X-23.1787 Y-12.6028 R2.0000

G02 X-4.5445 Y-22.3300 R27.5372

G03 X-2.8338 Y-22.0154 R1.0000

G02 X2.8338 Y-22.0154 R3.0000

G03 X4.5445 Y-22.3300 R1.0000

G02 X23.1787 Y-12.6028 R27.5372

G03 X25.0000 Y-10.6108 R2.0000

G01 X25.0000 Y-9.5000

G03 X24.5000 Y-9.0000 R0.5000

G01 X18.6548 Y-9.0000

G02 X18.1998 Y-8.2927 R0.5000

G03 X18.1998 Y8.2927 R20.0000

G02 X18.6548 Y9.0000 R0.5000

G01 X24.5000 Y9.0000

G03 X25.0000 Y9.5000 R0.5000

G01 X25.0000 Y10.6108

G03 X23.1787 Y12.6028 R2.0000

G02 X10.7873 Y16.8414 R27.5372

G03 X-10.7873 Y16.8414 R20.0000

G02 X-23.1787 Y12.6028 R27.5372

G03 X-25.0000 Y10.6108 R2.0000

G40G01 X-25.0000 Y25.6270

M02

欢迎提出意见和建议,根据用户的意见和建议改进和增强软件的功能

1.CAD齿轮与数控线切割软件面向什么样的行业用户?

CAD齿轮软件面向所有的机械行业,凡是有齿轮传动的地方都适合.飞机、汽车、轮船、机床、工业机器人、减速器、流量计、水稻插秧机、纺织机、印刷包装机、注塑机、模具、玩具、精密仪器与仪表......

数控线切割软件为数控线切割加工用户提供解决方案,同时生成G代码和3B代码,适合所有线切割机器,无论快走丝,中走丝,慢走丝,国产,进口. 适合所有数控铣床,无论国产,进口.

2.这个软件的优势和特点是什么?

一般的齿轮软件,只有计算,没有绘图,不直观.计算的结果是否正确,合理,很难判断.CAD齿轮软件在计算出结果的同时,立刻绘出图来,操作简单.可轻易地判别出计算的结果正确与否.绘出的齿轮图可用作三维建模,或直接数控线切割加工编程等,大幅提高生产率,降低生产成本.可按等滑动率计算变位系数,使齿轮啮合达到静音的效果。

数控线切割加工编程软件,是国内独创.线切割加工路径是可编辑的,而其他软件的线切割加工路径不可编辑.一旦加工路径出错,或要求修改,就没办法,这是本质区别.其他线切割软件在生成加工路径时,有时会出错或不能生成加工路径,本软件不会出现此种情况.支持多段线pline,样条线spline和椭圆(弧)ellipse,也是显著优于其它线切割软件的地方.

宇航CAD线切割软件

9.可实现快走丝3B代码与中、慢走丝G代码的相互转换.

10.可设置样条的加工精度,可无限精确. 样条线SPLINE既使有很密的点,也不影响加工效率,并支持椭圆弧。其它线切割软件无此功能。

11.能进行数控铣削和花纹图案的雕刻以及适用于点胶机.

12.能进行激光的切割与焊接.

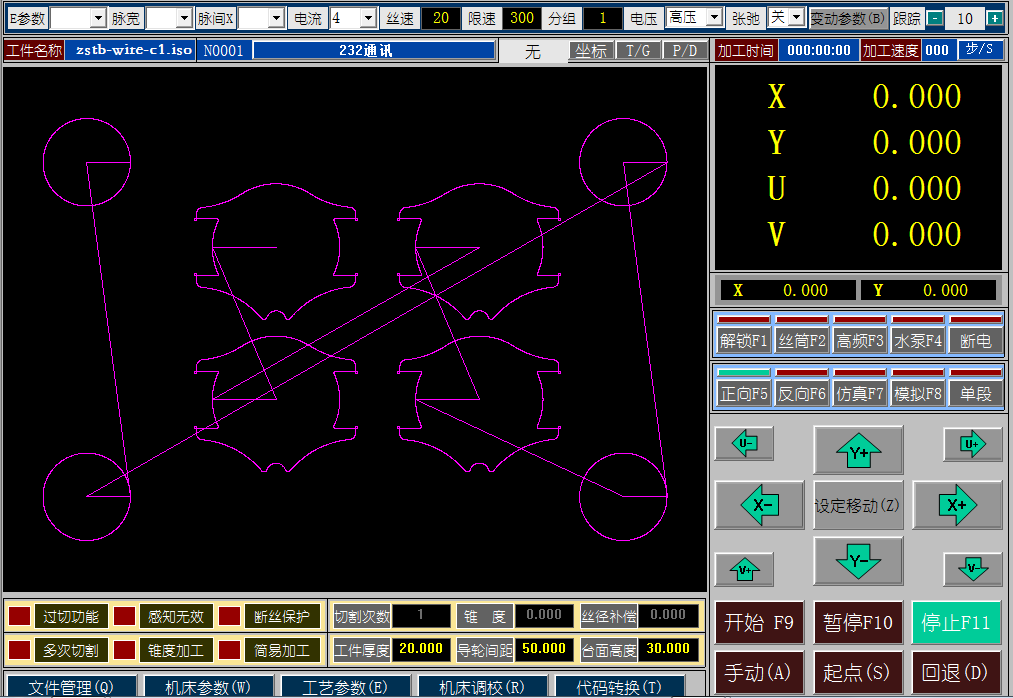

13.无须N+1次,只须1次生成割一修N次线切割加工程序,使线切割加工全自动化. 每次切割自动换电加工参数(脉宽,脉停,电流,波形等).

外切割和内切割及切割方向由引导线决定(红色的是连为一体的PLINE线);圆的切割方向由程序设定(顺时针或逆时针)。

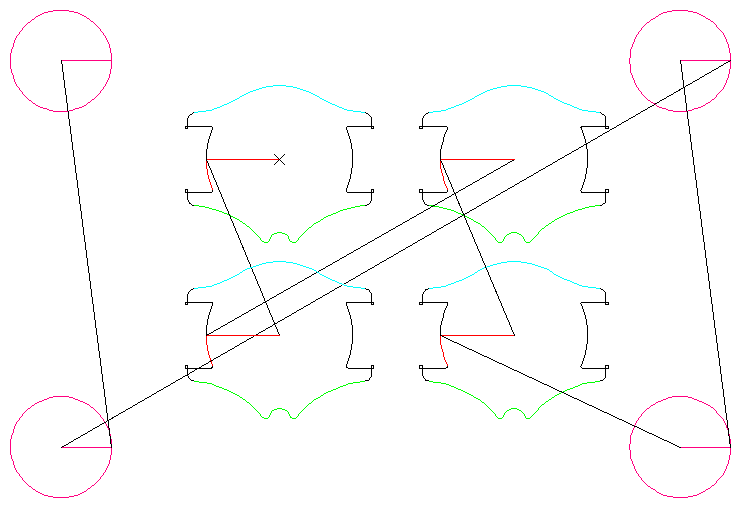

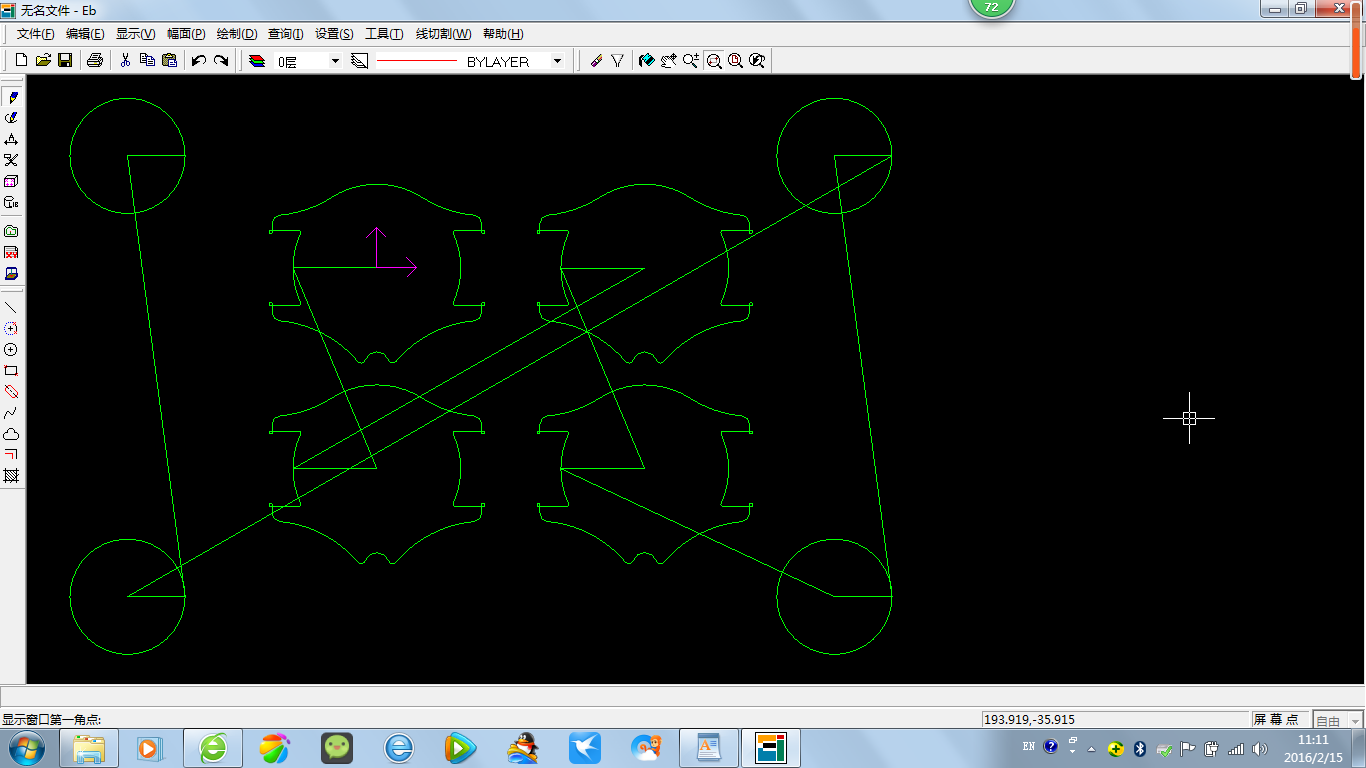

14.全自动一次性生成所有型腔的线切割加工程序,各型腔之间直线跳步.大大地提高线切割编程人员编制加工程序的效率,降低编程人员的劳动强度.

实现快、中、慢走丝跳步的全自动编程,举世无双

宇航CAD,引领新一波工业革命浪潮!

15.可事先确定逆时针切割还是顺时针切割.

16.无需转DXF,直接在CAD中运行,避免因转DXF而导致图形的曲线变形.无须学习其它复杂的线切割软件,只须在CAD中加载运行一CAD命令,就可把CAD图形转化为加工代码,省时省力.

~~~~~~~~~~~~~~~~~~~~

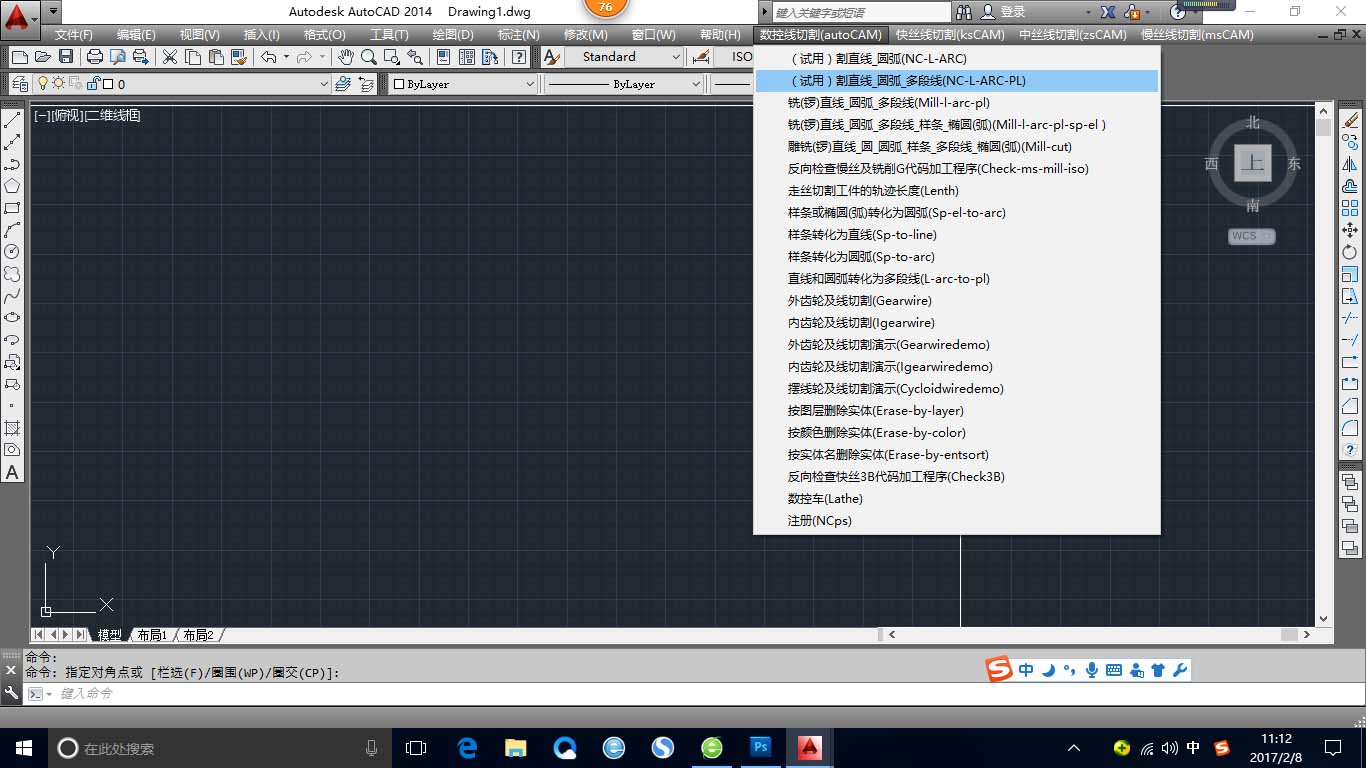

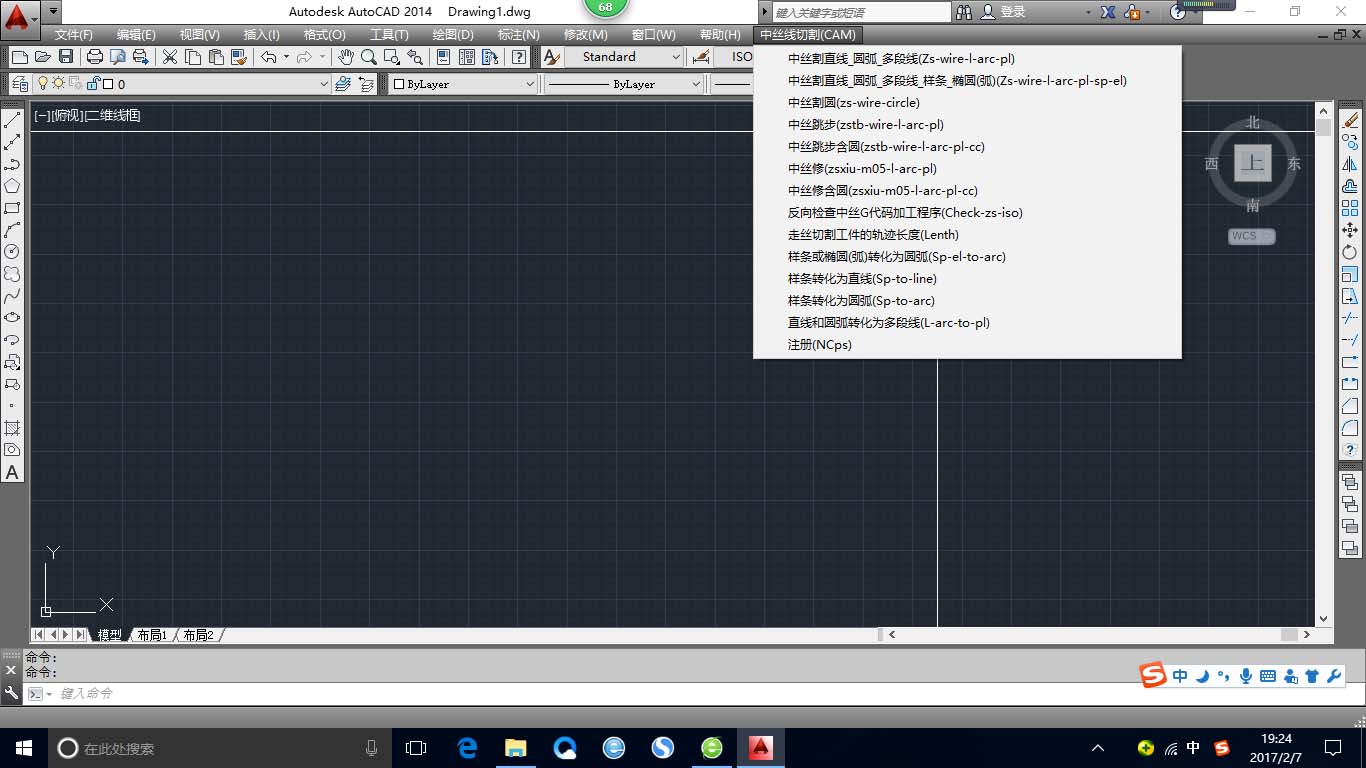

在CAD中, 加载数控线切割菜单, 输入menu命令,点aerocam.mnu文件.

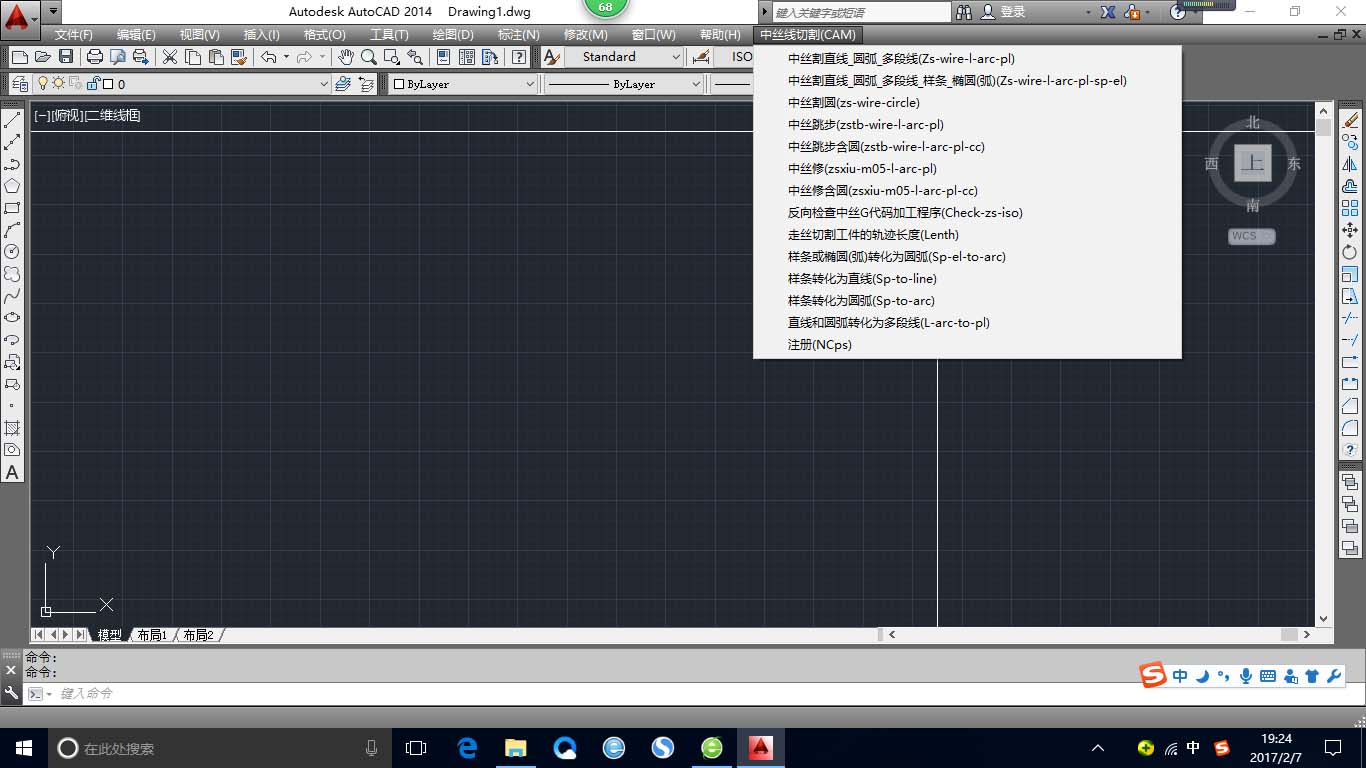

中走丝,在CAD中, 加载中走丝线切割菜单, 输入menu命令,点zscam.mnu文件.

恢复原菜单,输入menu,点acad.mnu文件或acad.mnx或acad.cui或acad.cuix文件.

~~~~~~~~~~~~~~~~~

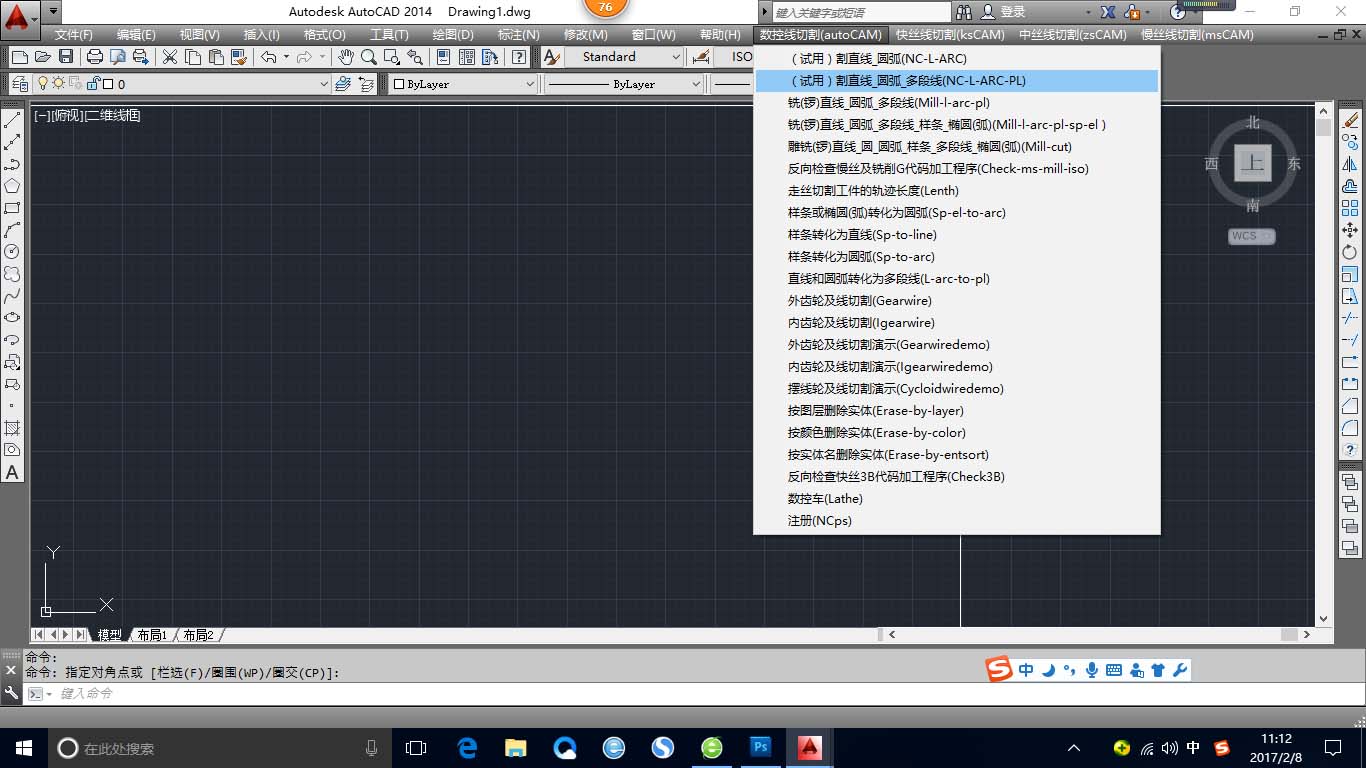

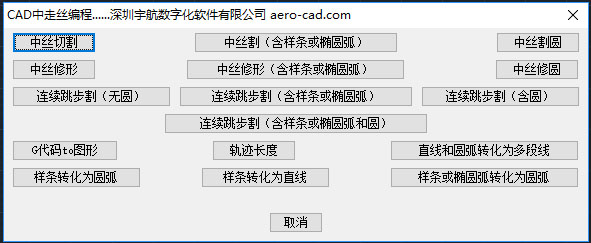

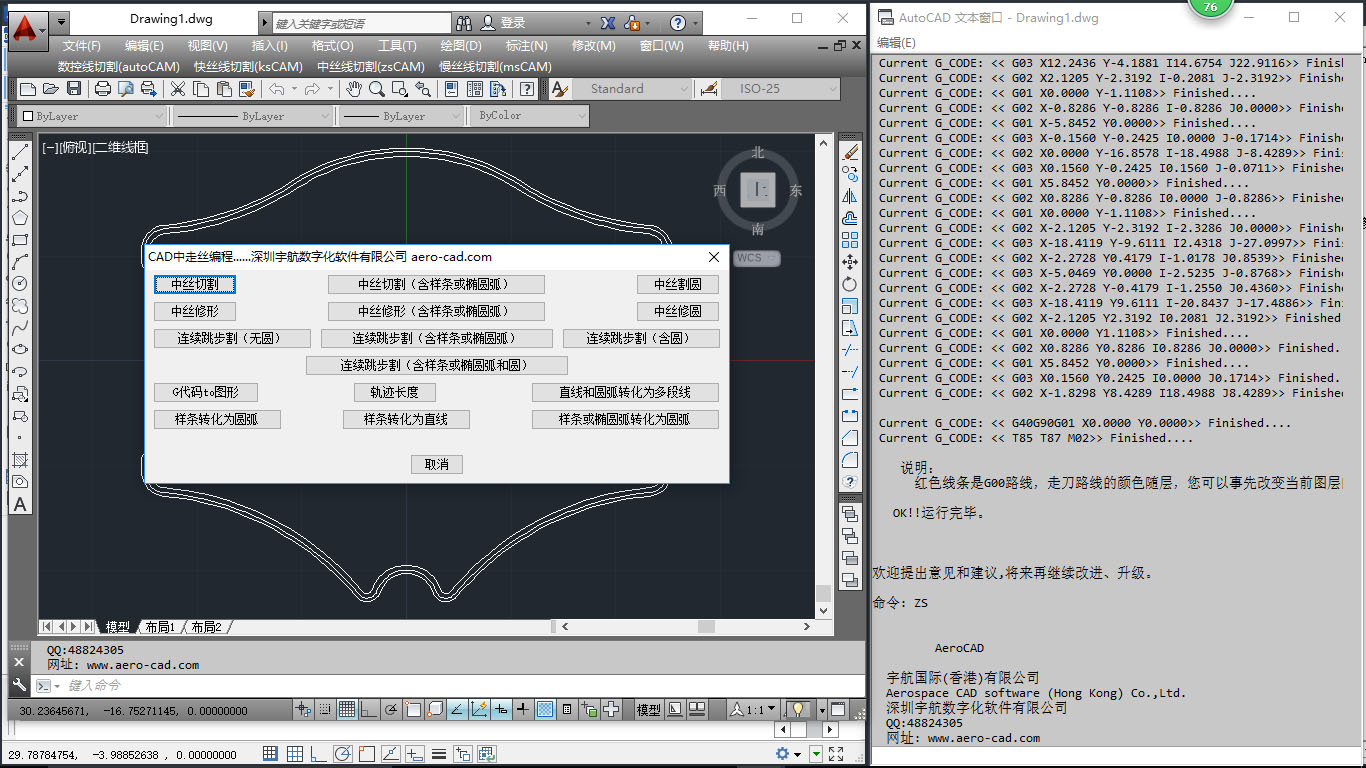

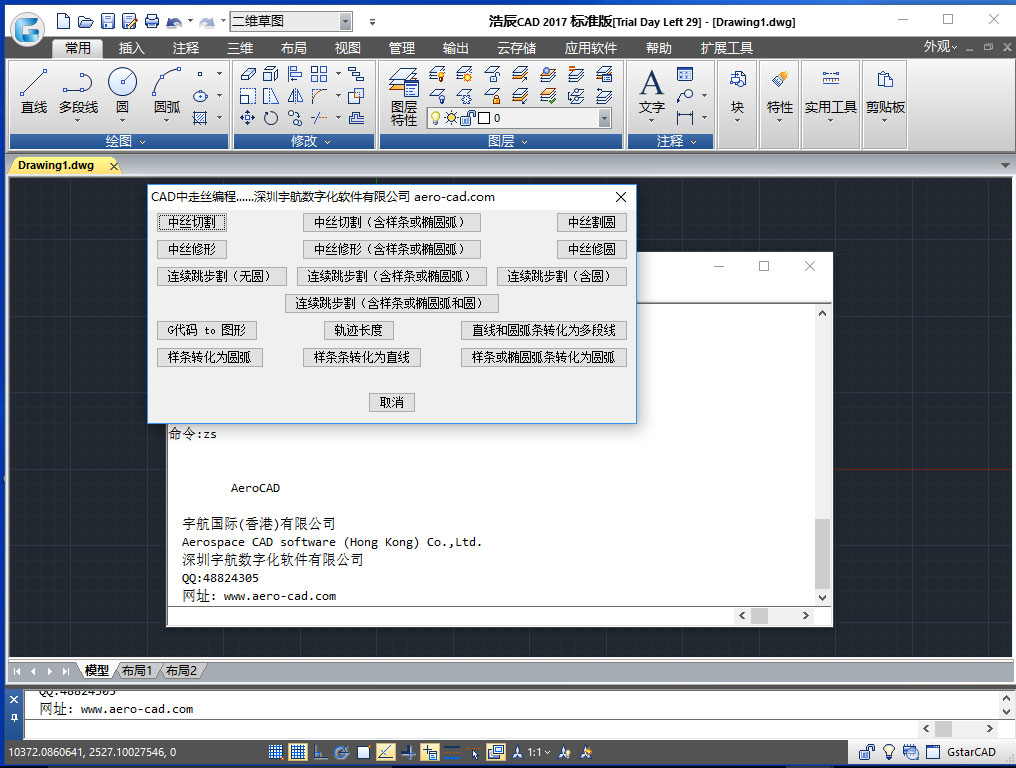

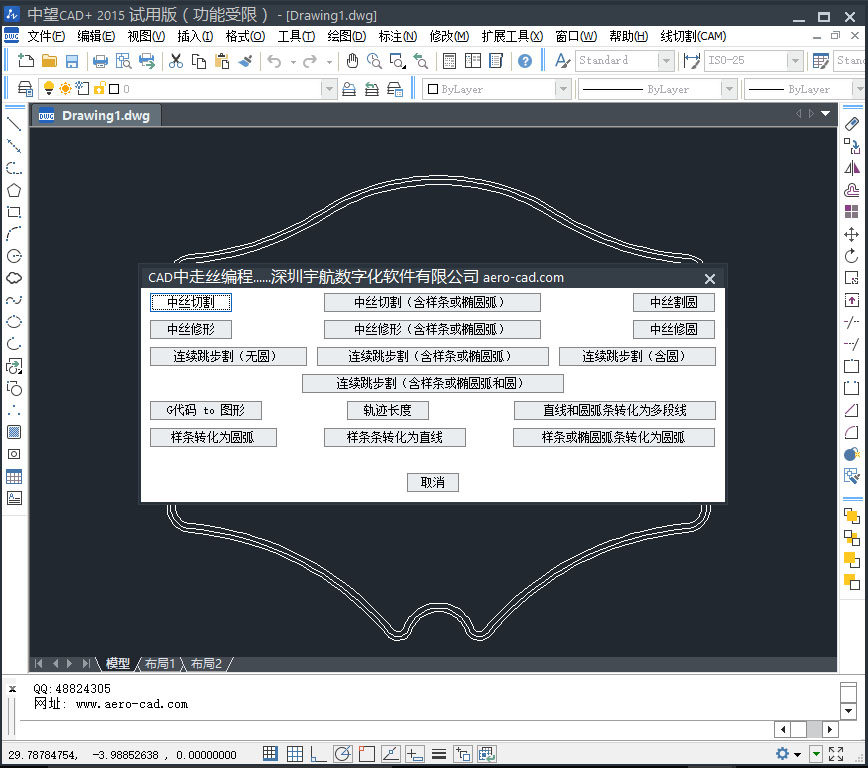

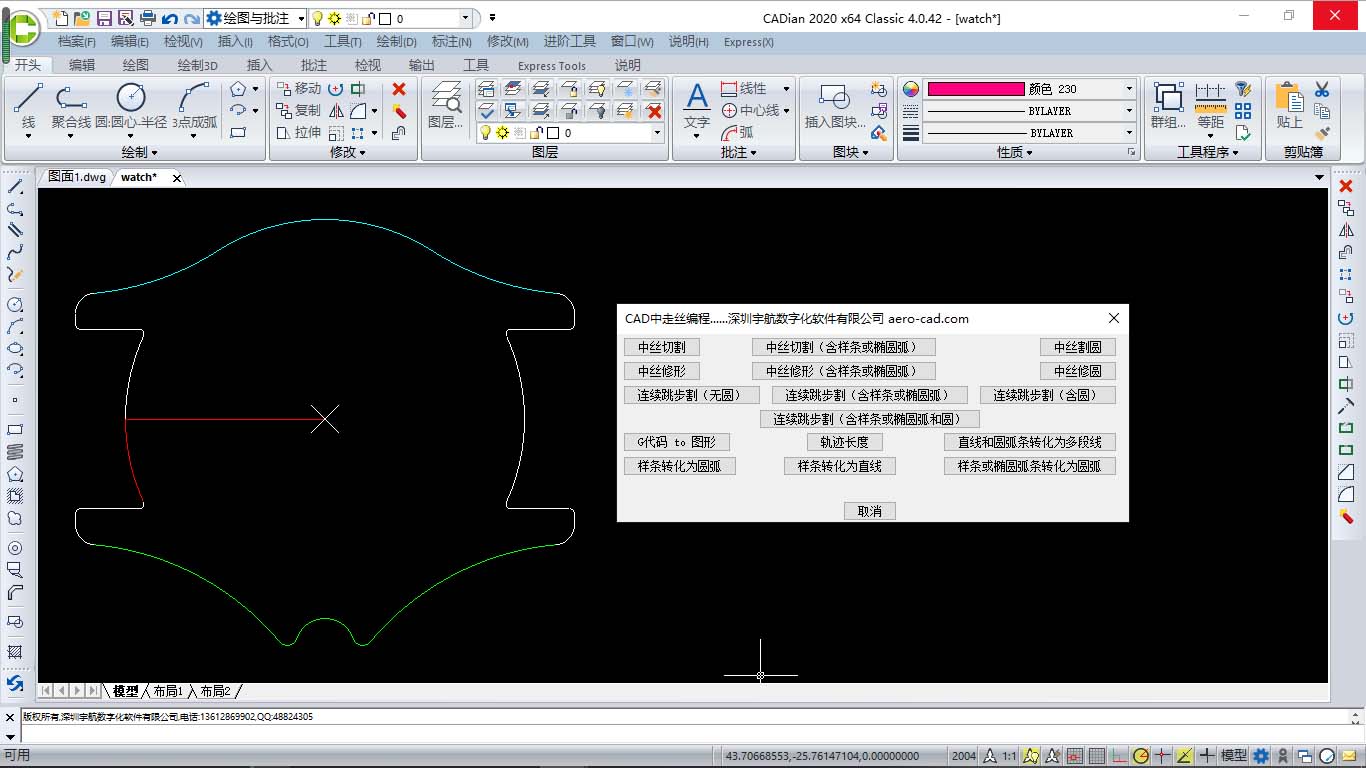

现在可以按钮形式运行功能,无需菜单了。好处是不需按CAD版本或品牌来加载菜单文件,原有菜单不变,也不需经典菜单模式。任何版本或品牌的CAD平台(AutoCAD、韩国CADian、中望CAD、浩辰CAD)都是以下相同的介面:

韩国CADian:

友情链接:

CAD线切割软件 |

CAD线切割软件 |

CAD线切割软件 |

CAD线切割软件 |

|

让中国再伟大

宇航國際(香港)有限公司

Aerospace CAD software (Hong Kong) Co., Ltd.

地址:香港九龍旺角道33號凱途發展大廈7樓04室

ADDRESS:UNIT 04,7/F,BRIGHT WAY TOWER,NO.33 MONG KOK ROAD,KOWLOON,HONG KONG

电话(TEL):(00852)65171898 27935511 邮箱: mcga@aero-cad.com 传真(FAX):(00852)35902333

深圳宇航数字化软件有限公司

地址:深圳市福田区深南中路2010号东风大厦2013室(地铁科学馆站)

电话:0755-32927869 15217068508 13612869902

Make China Great Again