详细说明

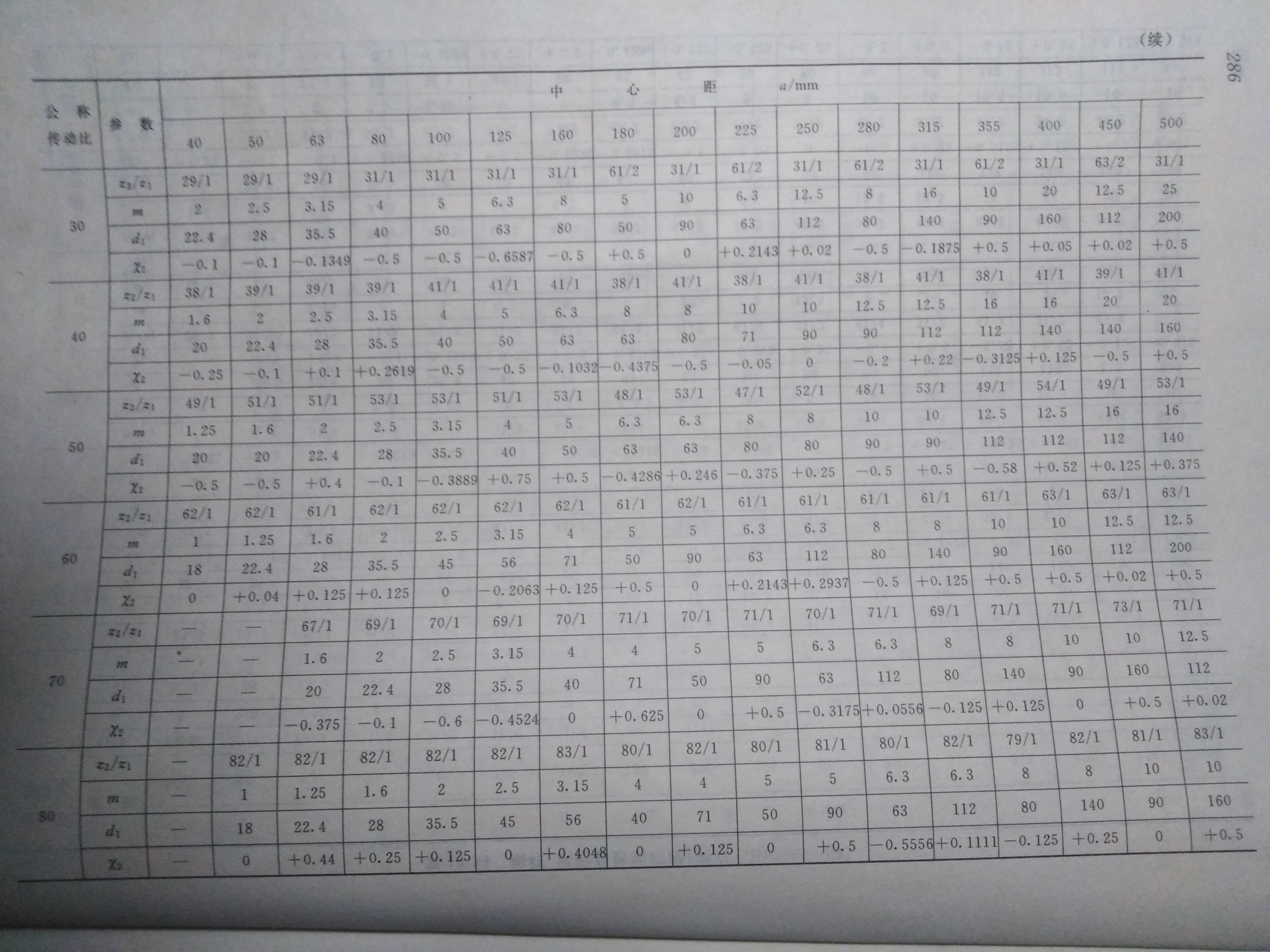

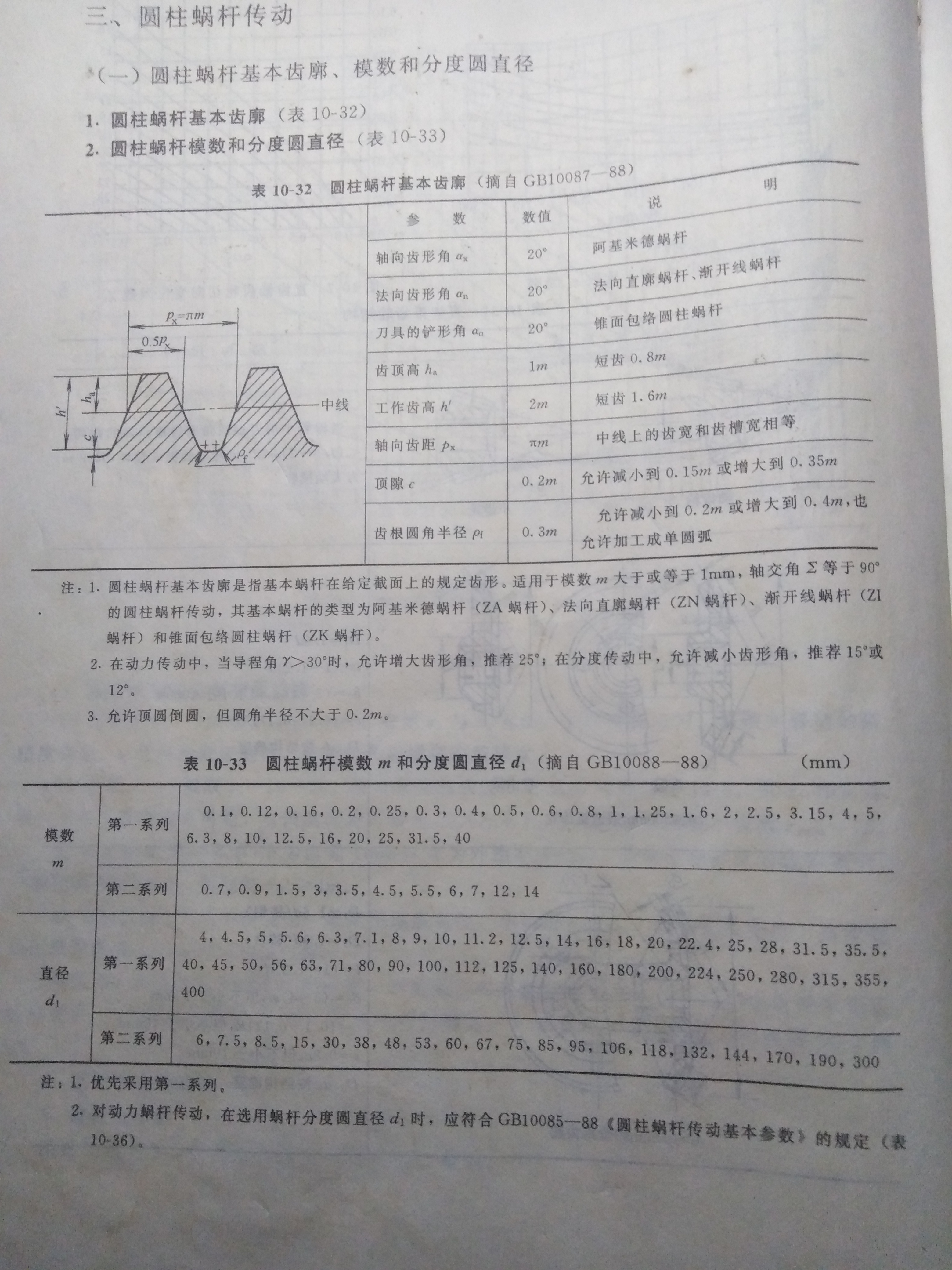

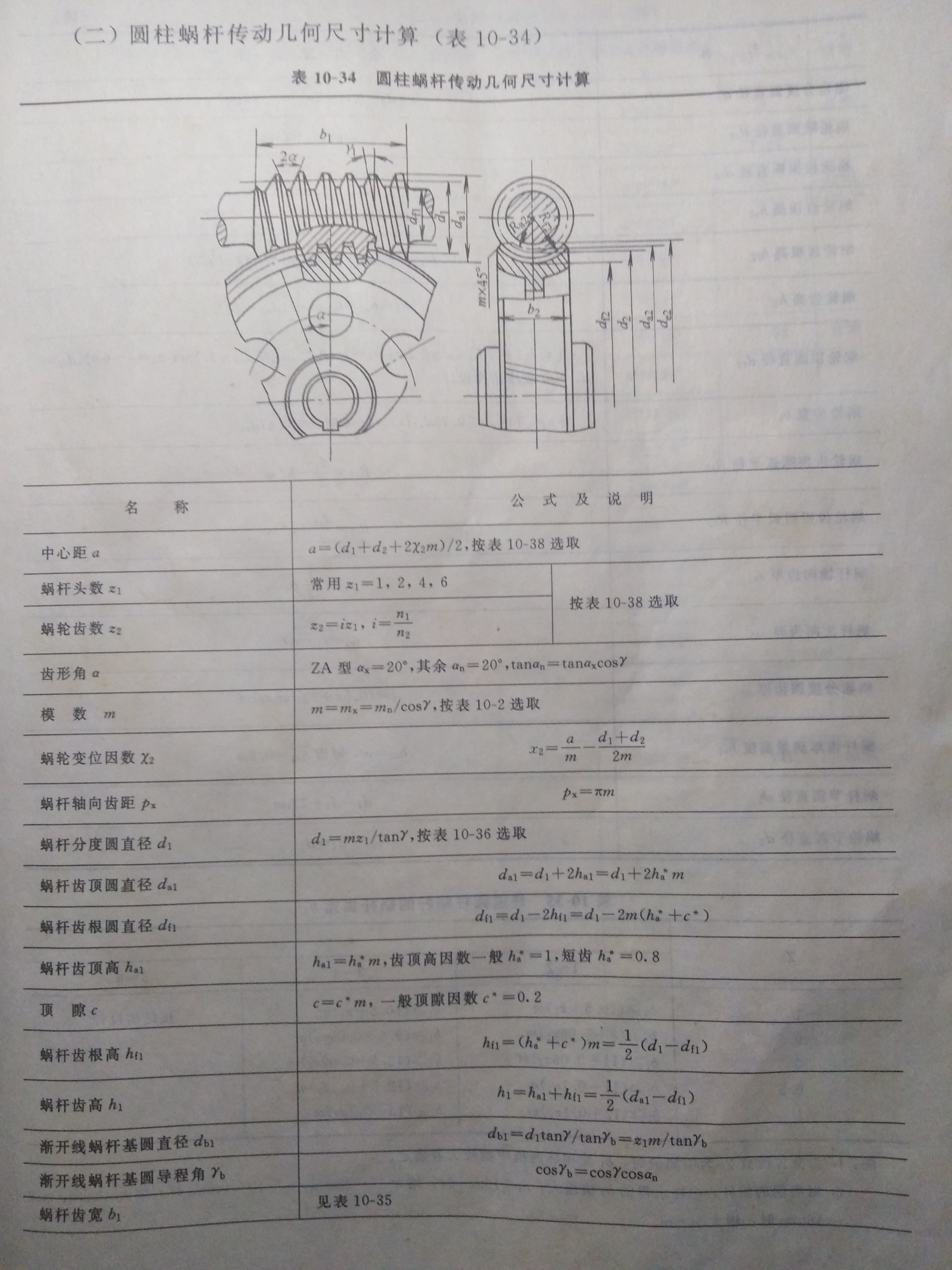

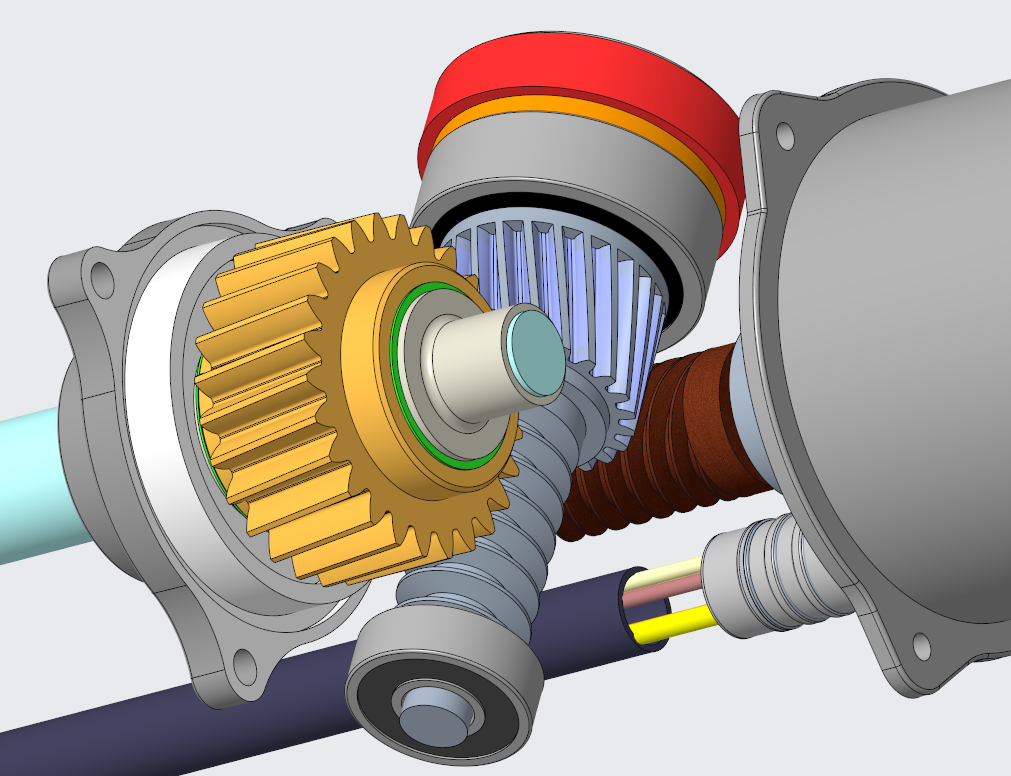

普通圆柱蜗杆传动几何尺寸计算

普通圆柱蜗杆传动几何尺寸计算

(轴交角90度,已知中心距)

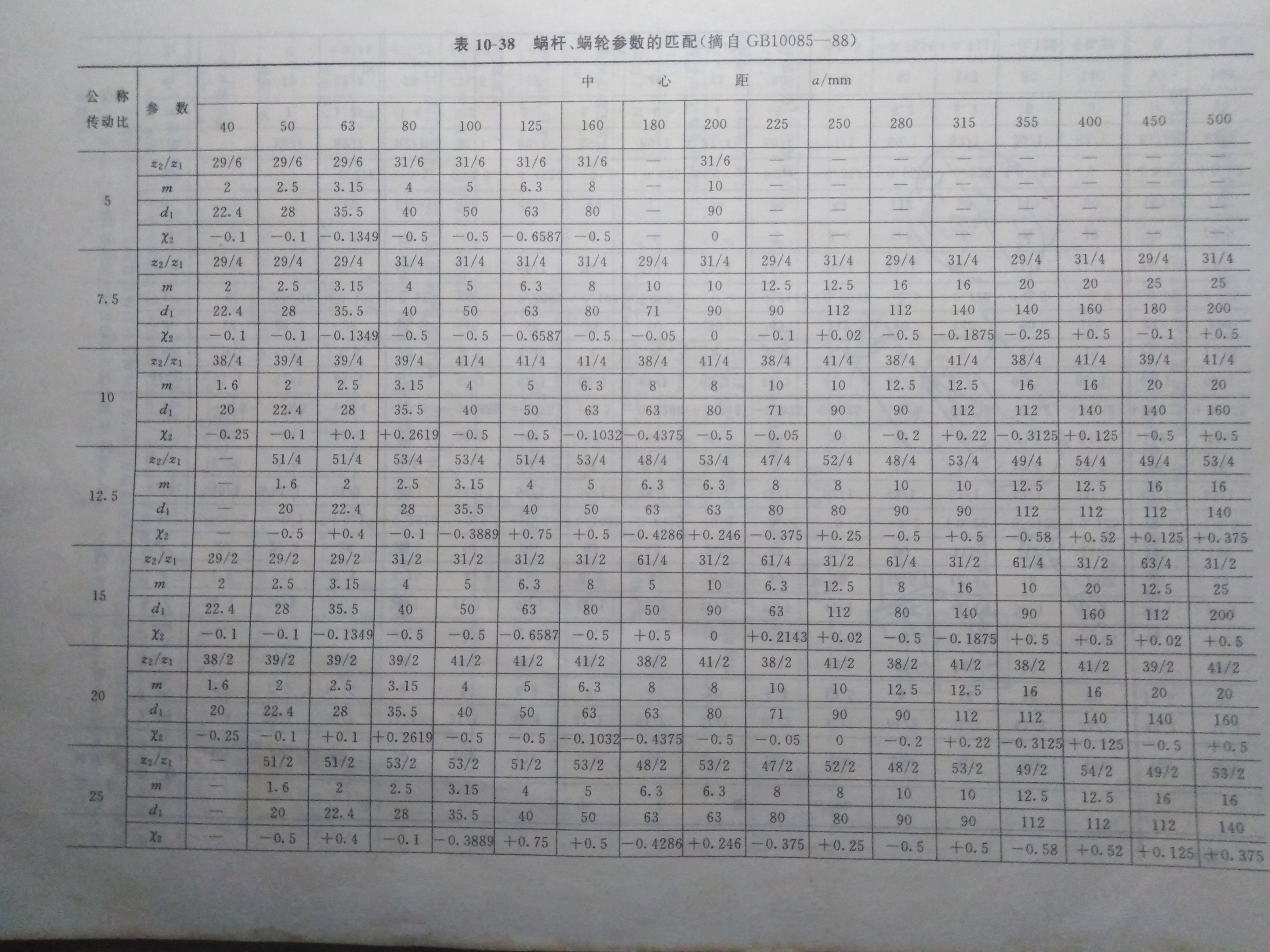

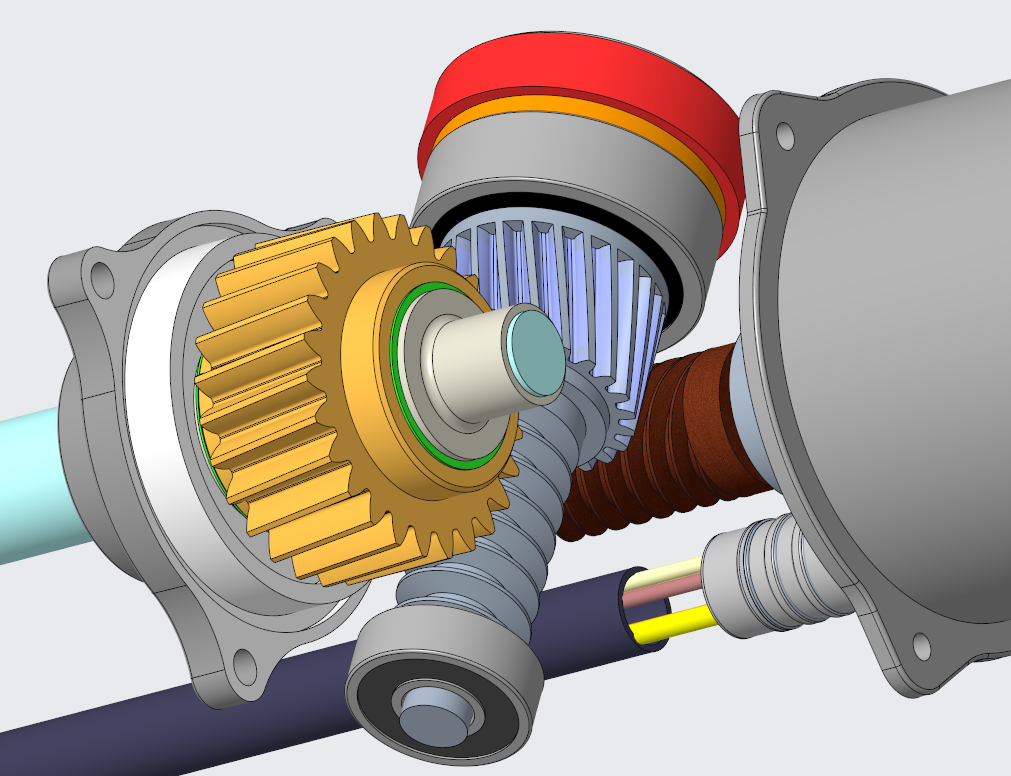

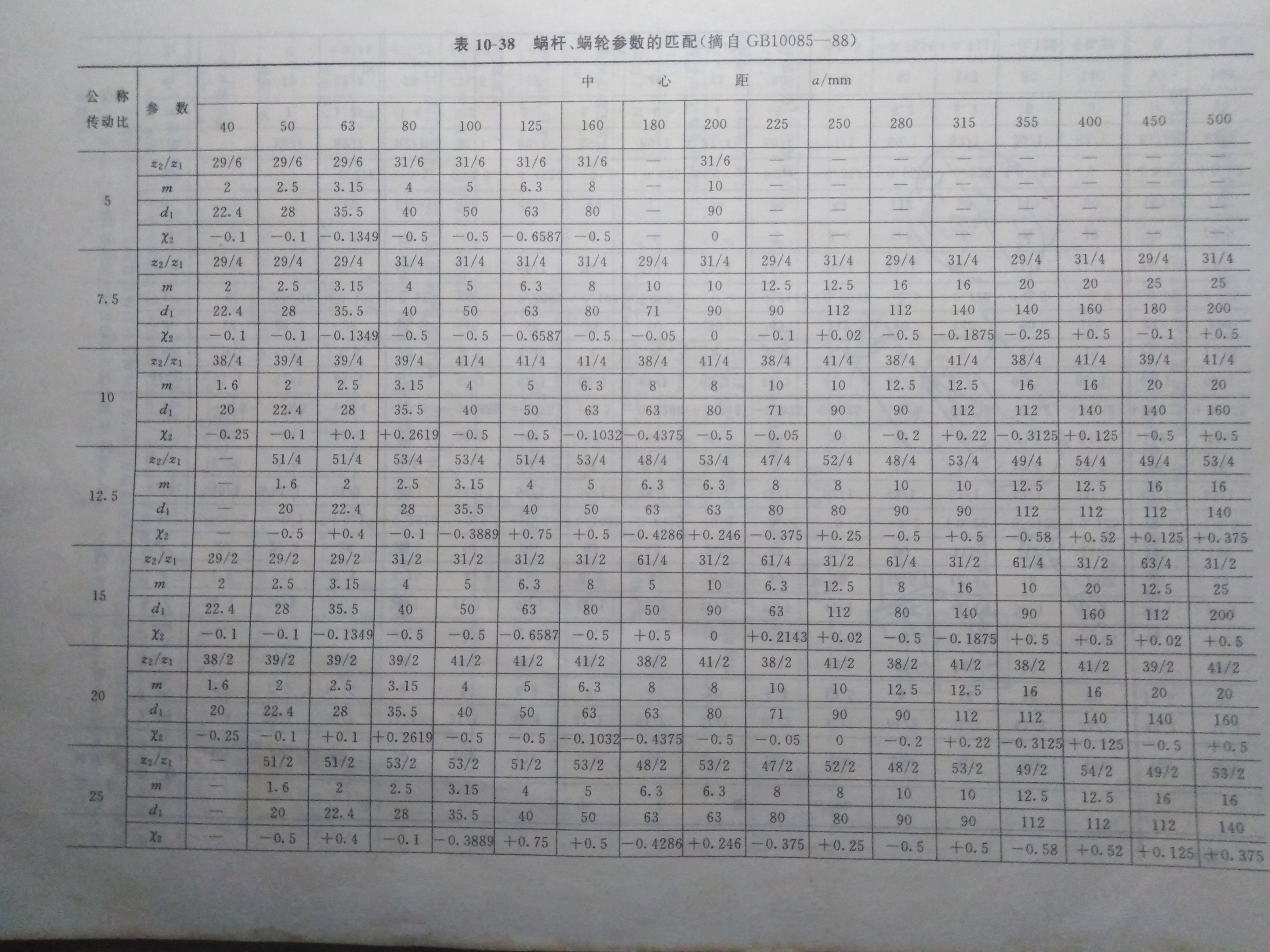

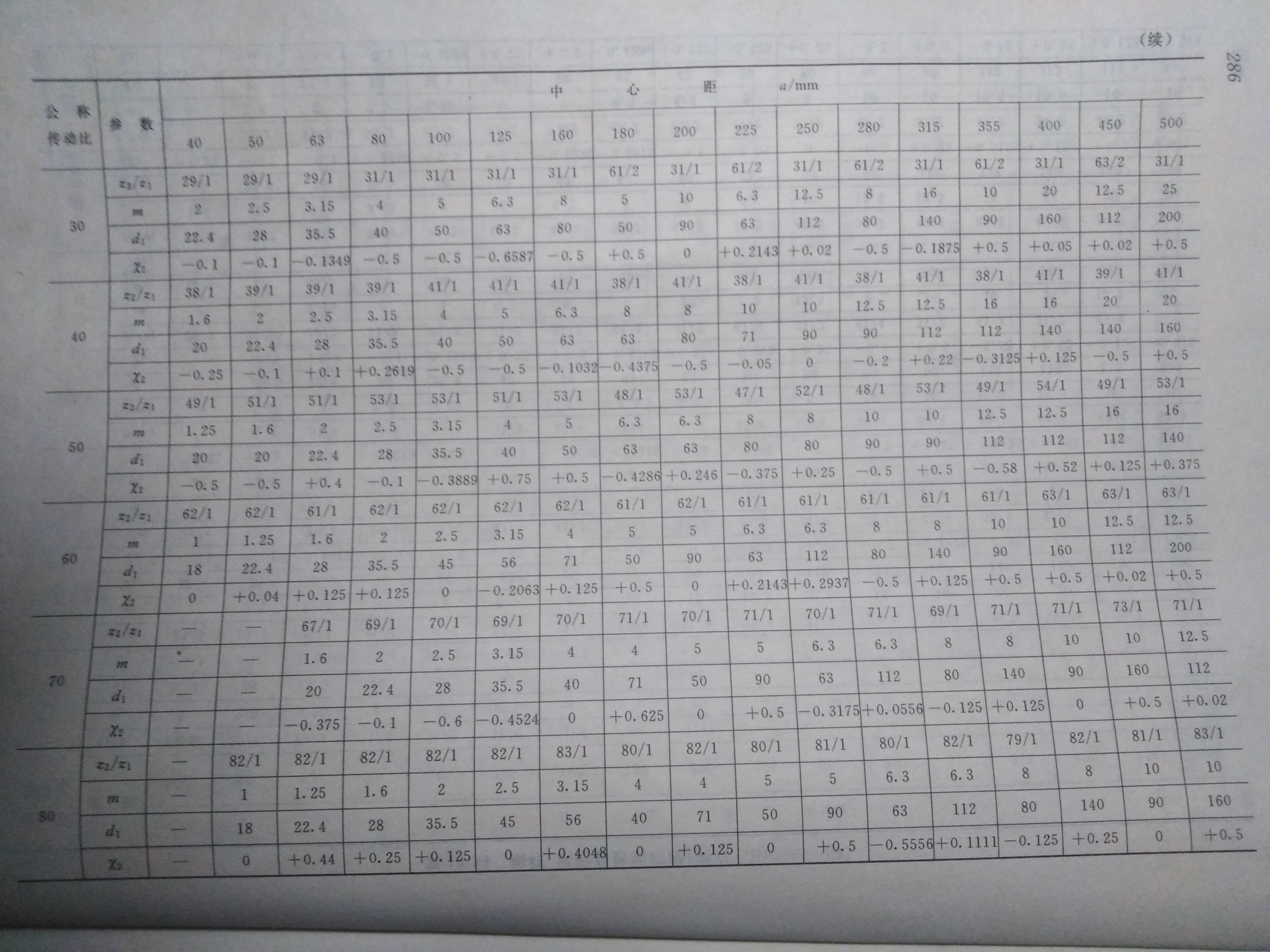

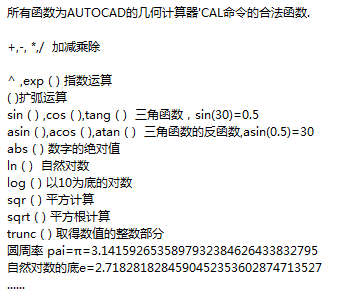

啮合中心距:A=100 ;中心距a=(d1+d2+2.0*x2*m)/2.0,按表10-38选取.

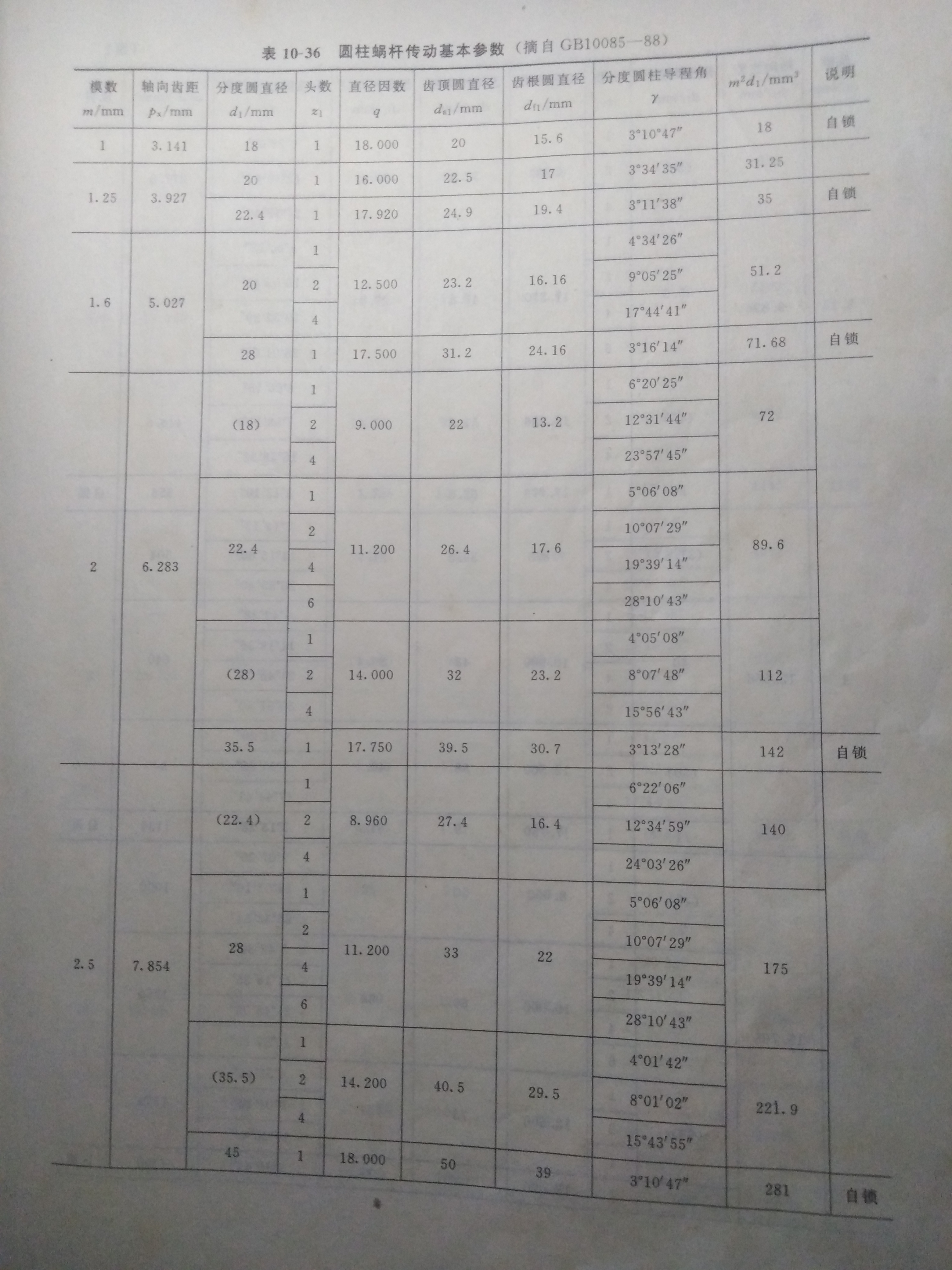

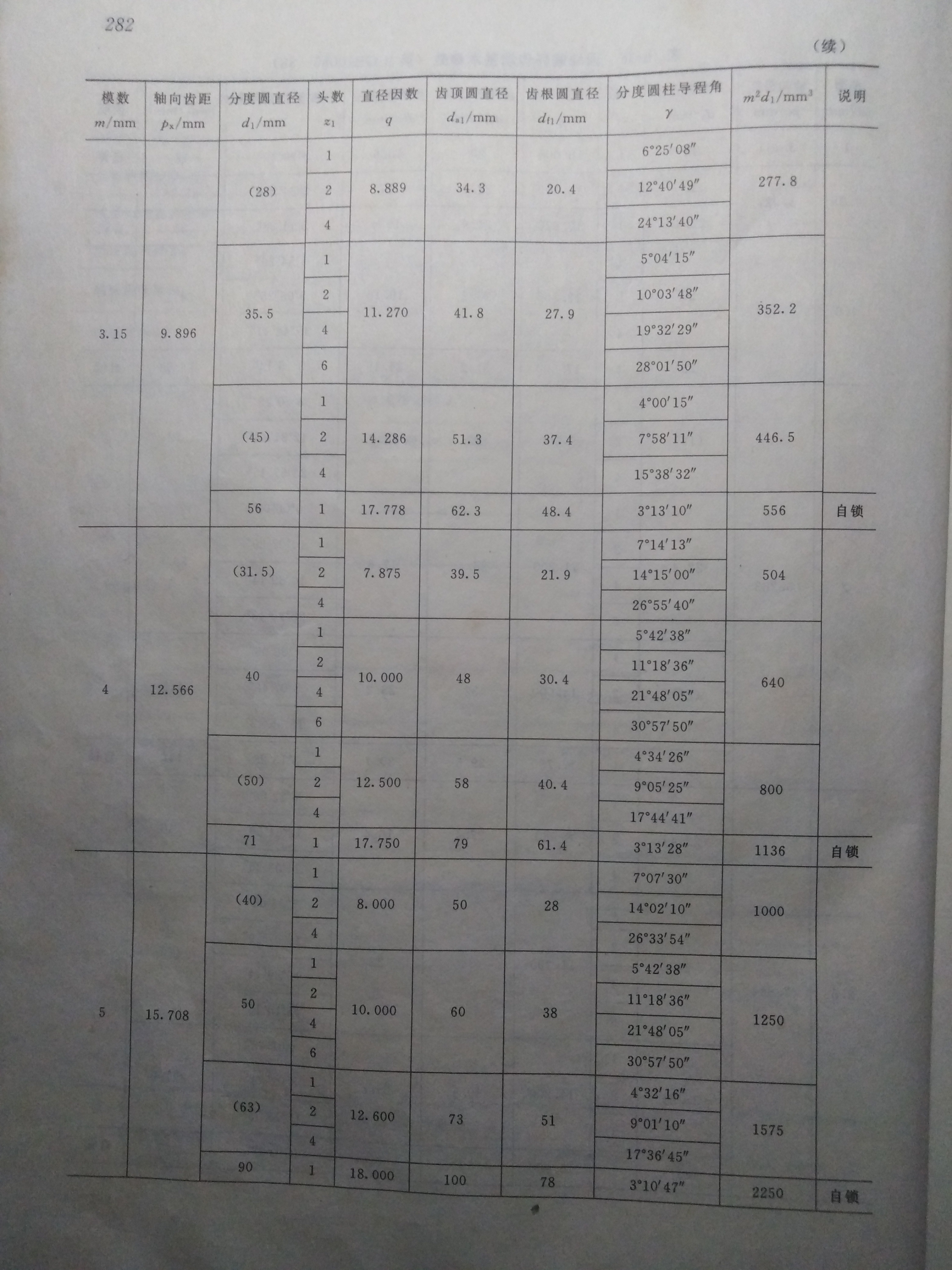

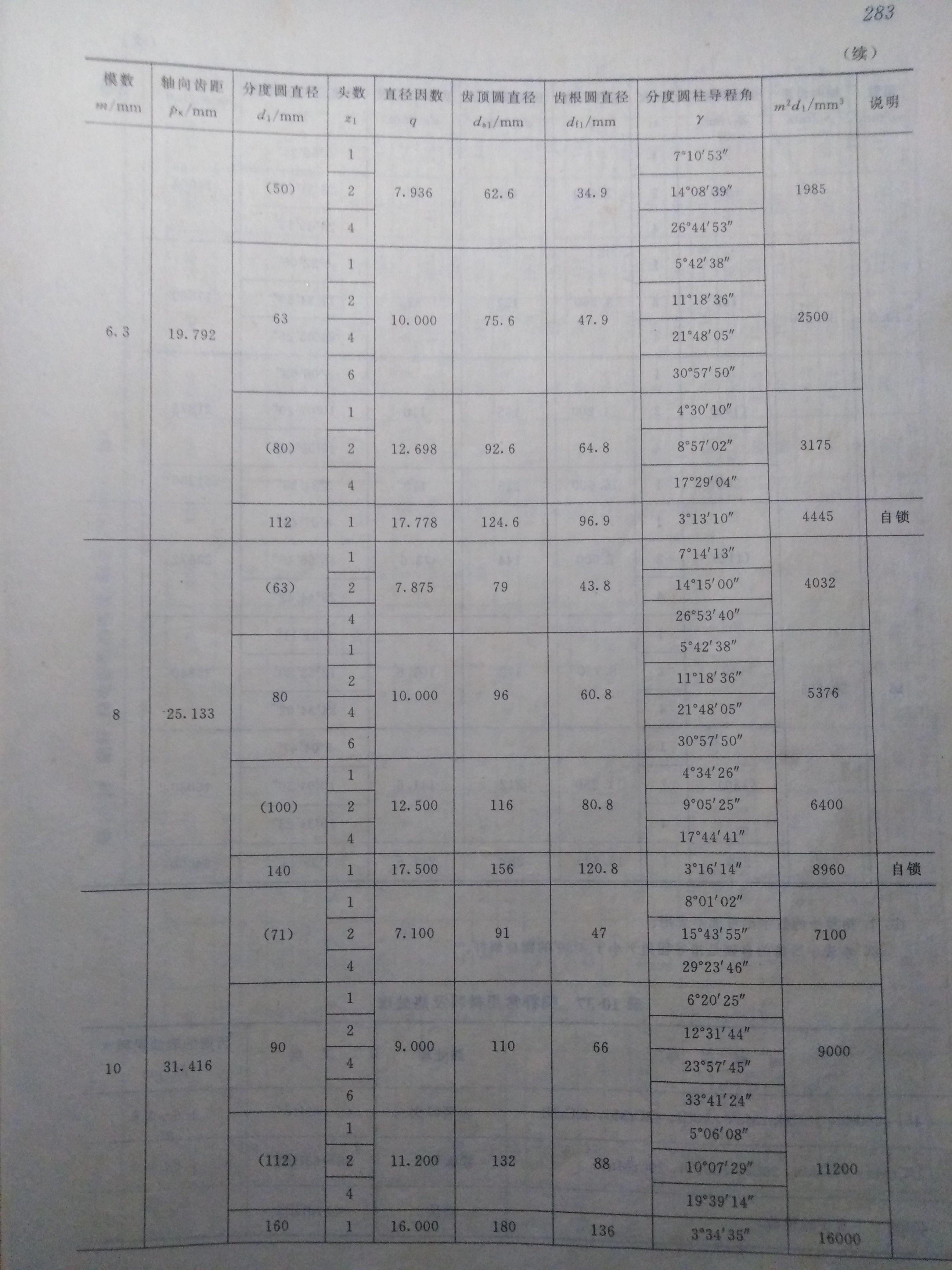

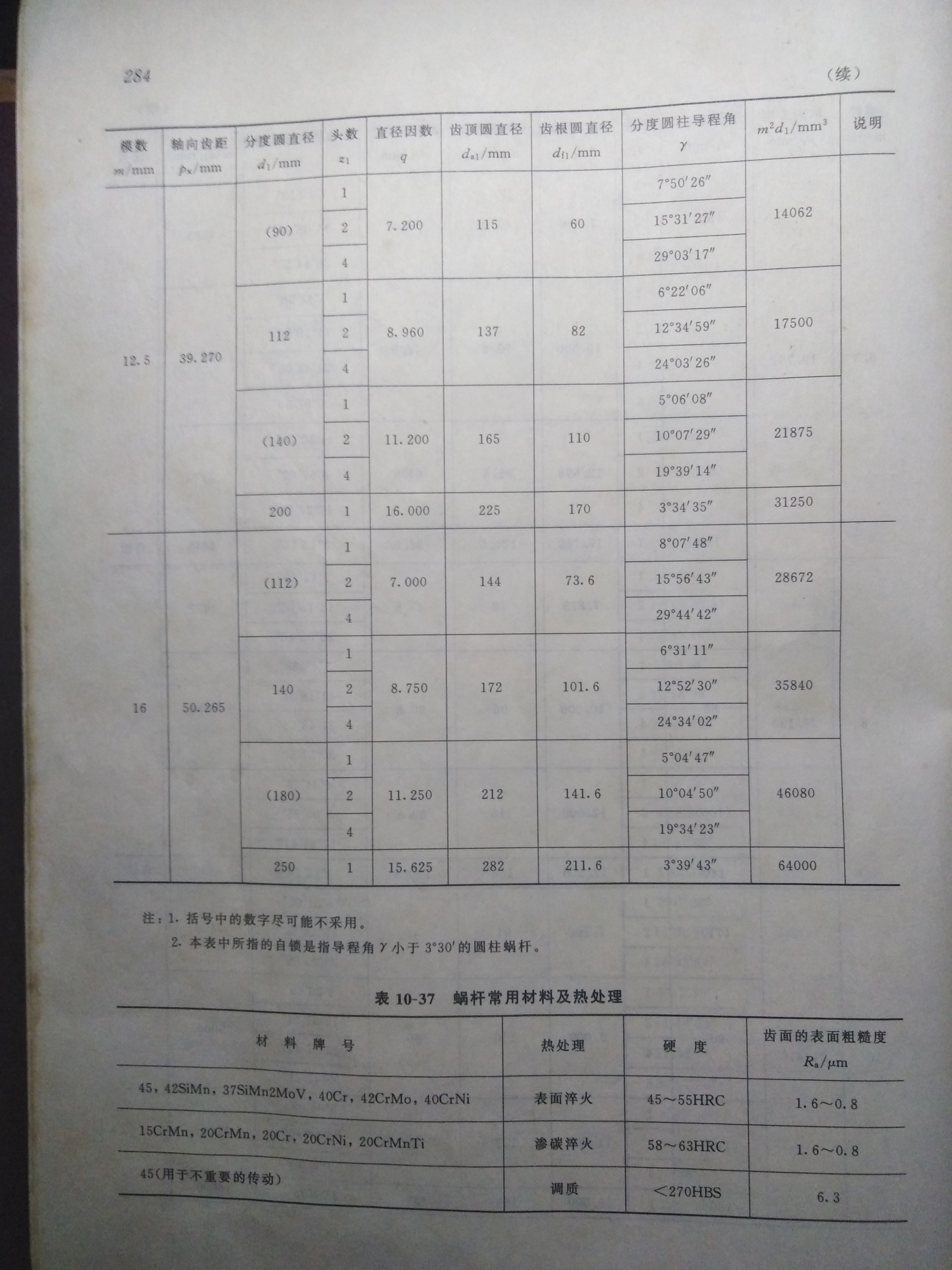

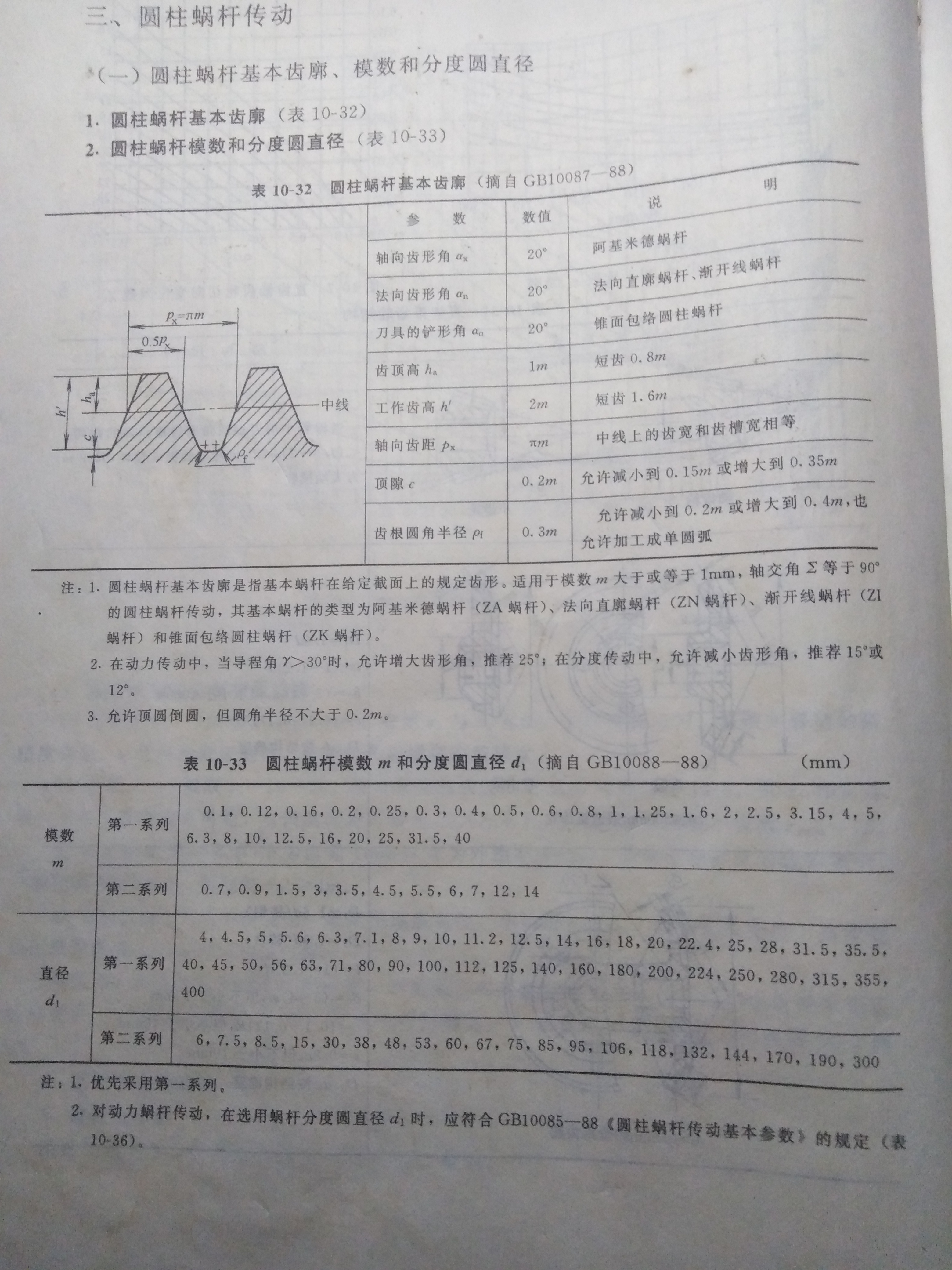

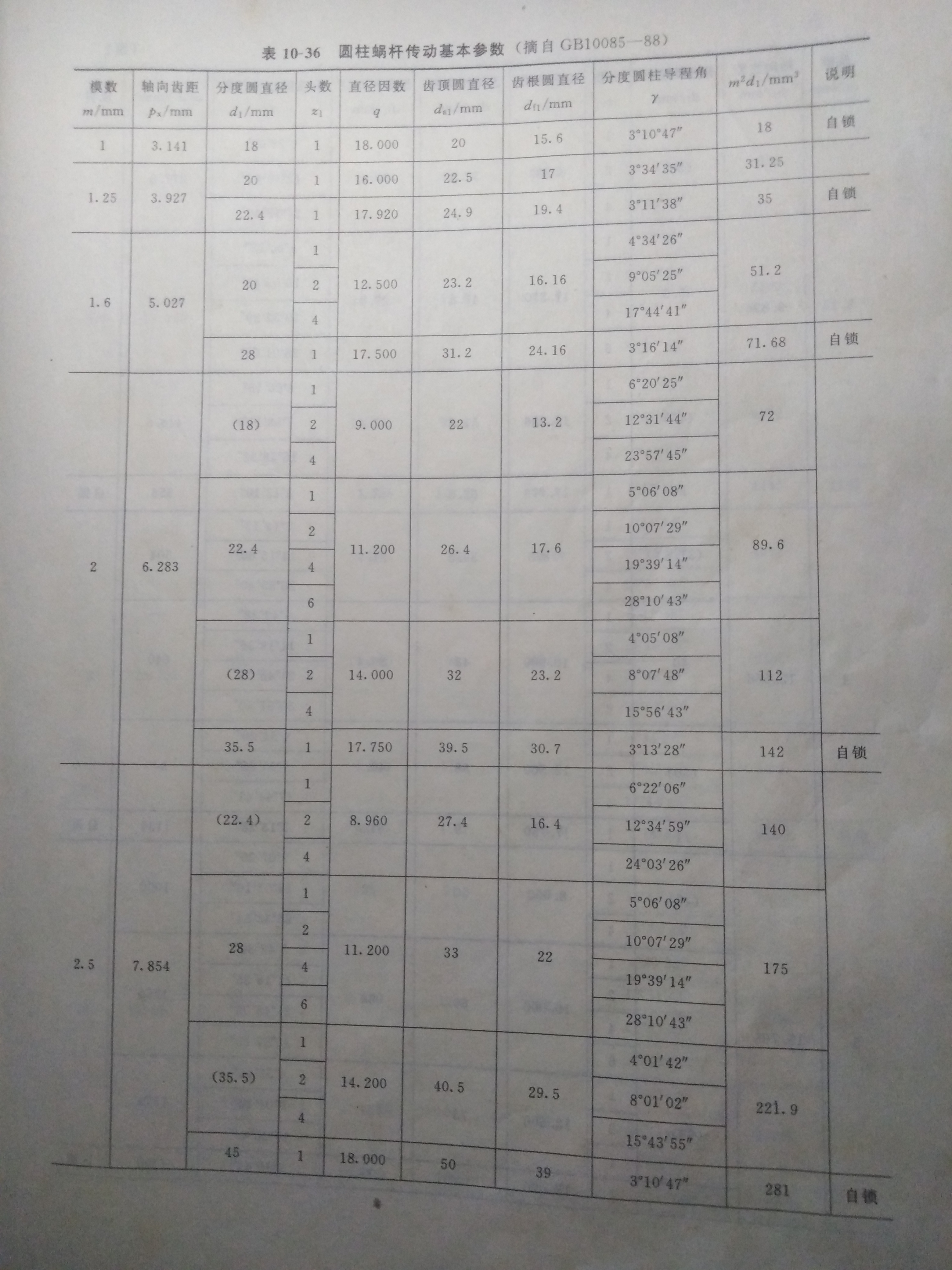

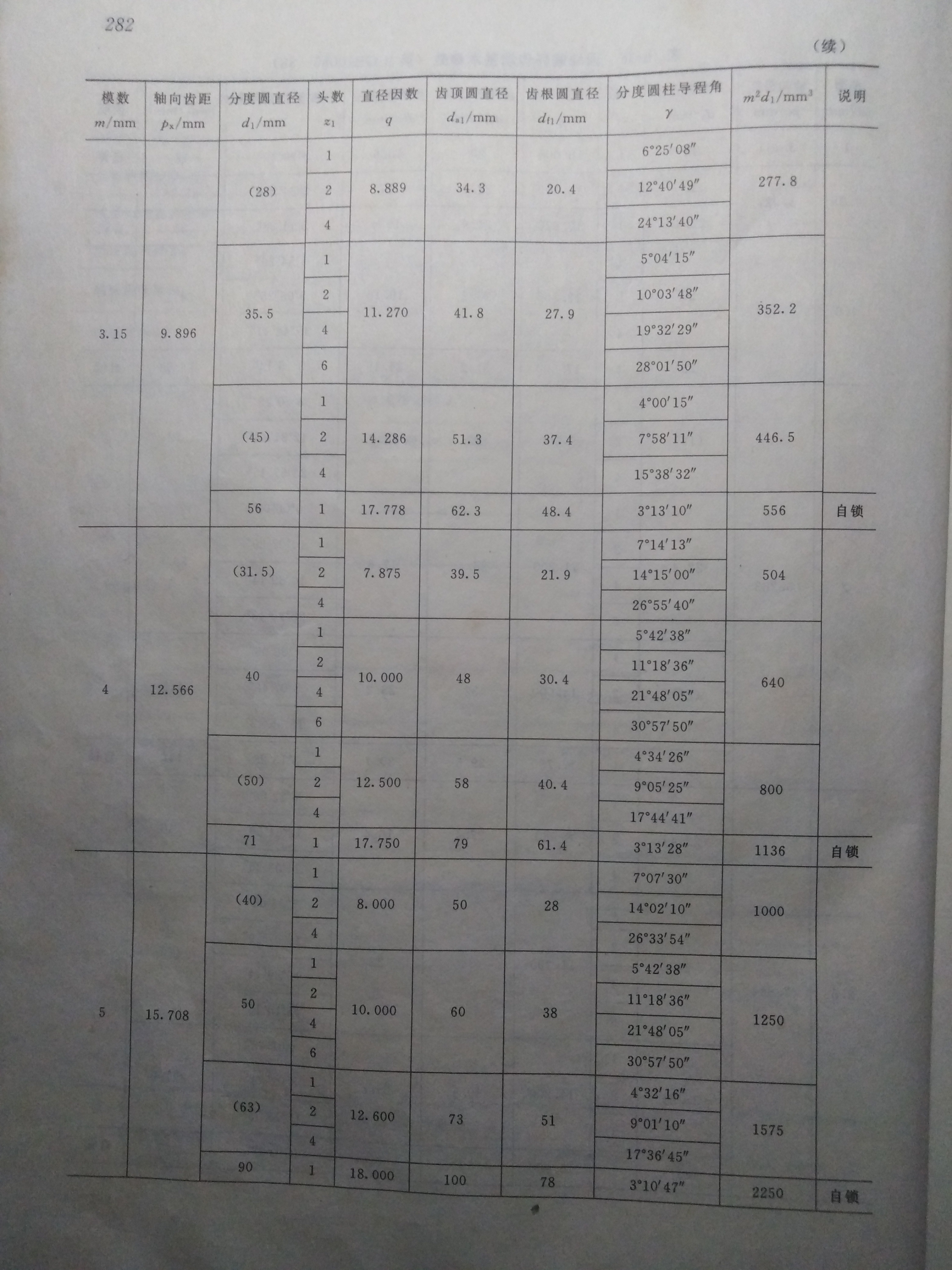

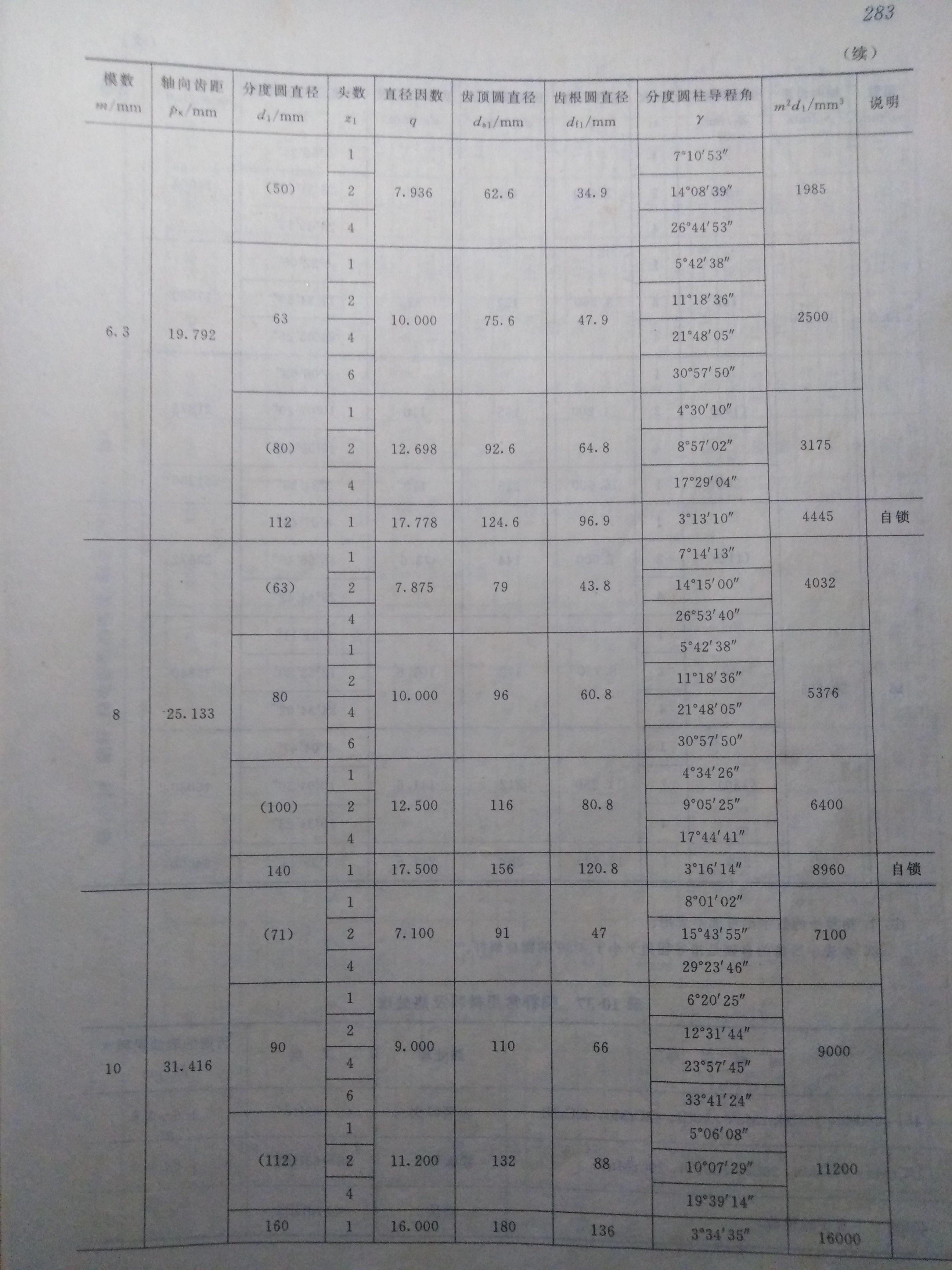

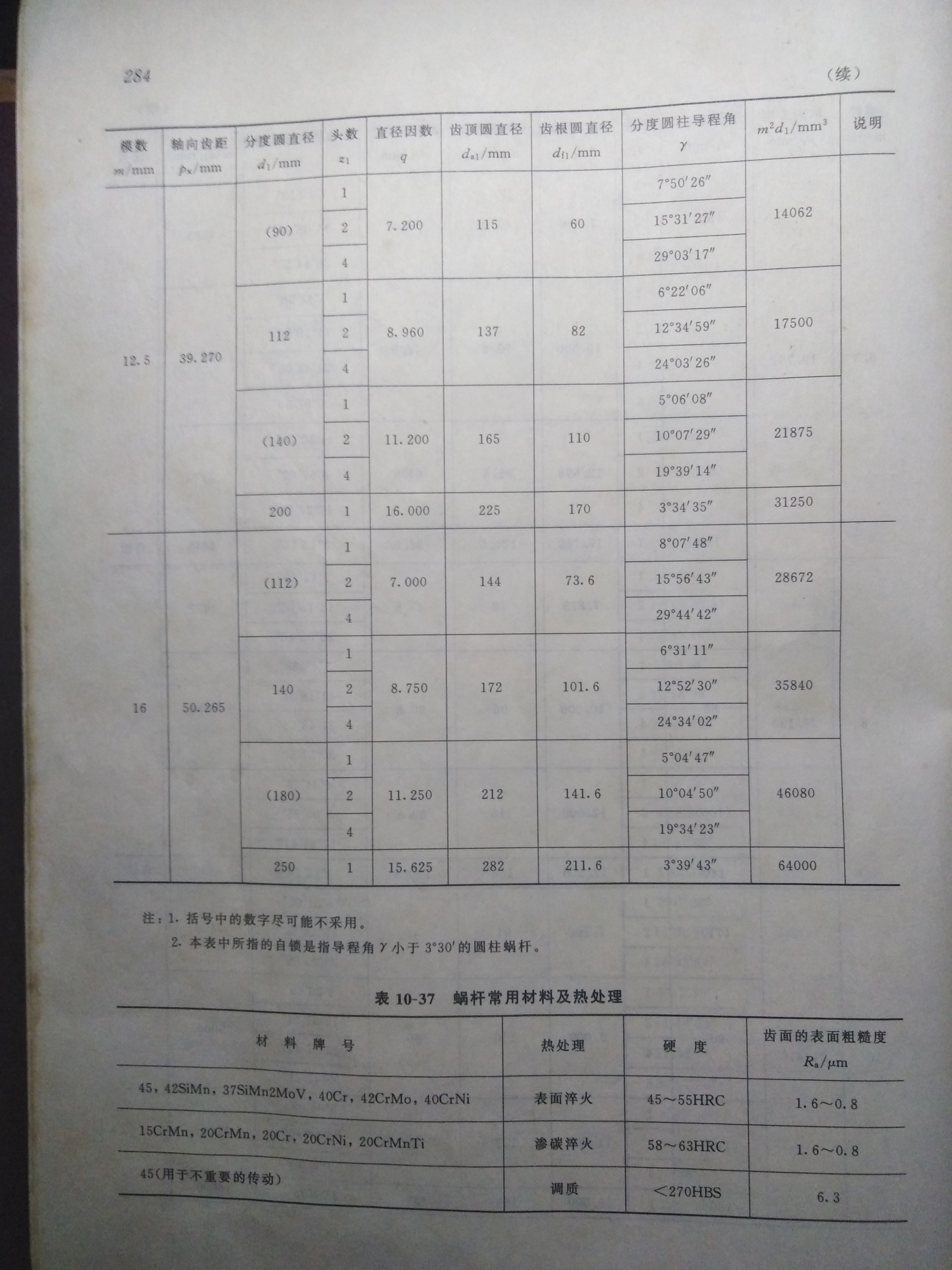

蜗杆轴向模数:m=5 ;按表10-38选取.

蜗杆头数:z1=1 ;常用1,2,4,6,按表10-38选取.

蜗杆分度圆直径:d1=50 ;d1=m*z1/tang(r),按表10-36选取.

蜗轮齿数:z2=31 ;z2=i*z1,i=n1/n2,按表10-38选取.

蜗轮分度圆直径:d2=m*z2

蜗杆直径系数:q=d1/m

齿数比:u=z2/z1

蜗轮变位系数:x2=-0.5 ;x2=A/m-0.5*(q+z2) =A/m-0.5*(d1+d2)/m,按表10-38选取.

蜗杆分度圆柱导程角:r=atan(z1/q)

法向模数:mn=m*cos(r)

蜗杆轴向齿距:px1=pi*m

蜗杆螺旋线导程:pz1=px1*m

蜗杆轴向齿形角:angle=20

蜗杆节圆直径:d_1=(q+2*x2)*m

蜗杆节圆柱导程角:r1=atan(z1/(q+2*x2))

渐开线蜗杆:

基圆柱导程角:rb=acos(cos(angle)*cos(r))

基圆直径:db1=z1*m/tang(rb)

法向基节:pbm=pi*m*cos(rb)

蜗杆齿顶高:ha1=m

蜗杆齿根高:hf1=1.2*m

蜗杆全齿高:h1=ha1+hf1

顶隙:c1=0.2*m

齿根圆角半径:pf=0.3*m

蜗杆齿顶圆直径:da1=d1+2*ha1

蜗杆齿根圆直径:df1=d1-hf1*2

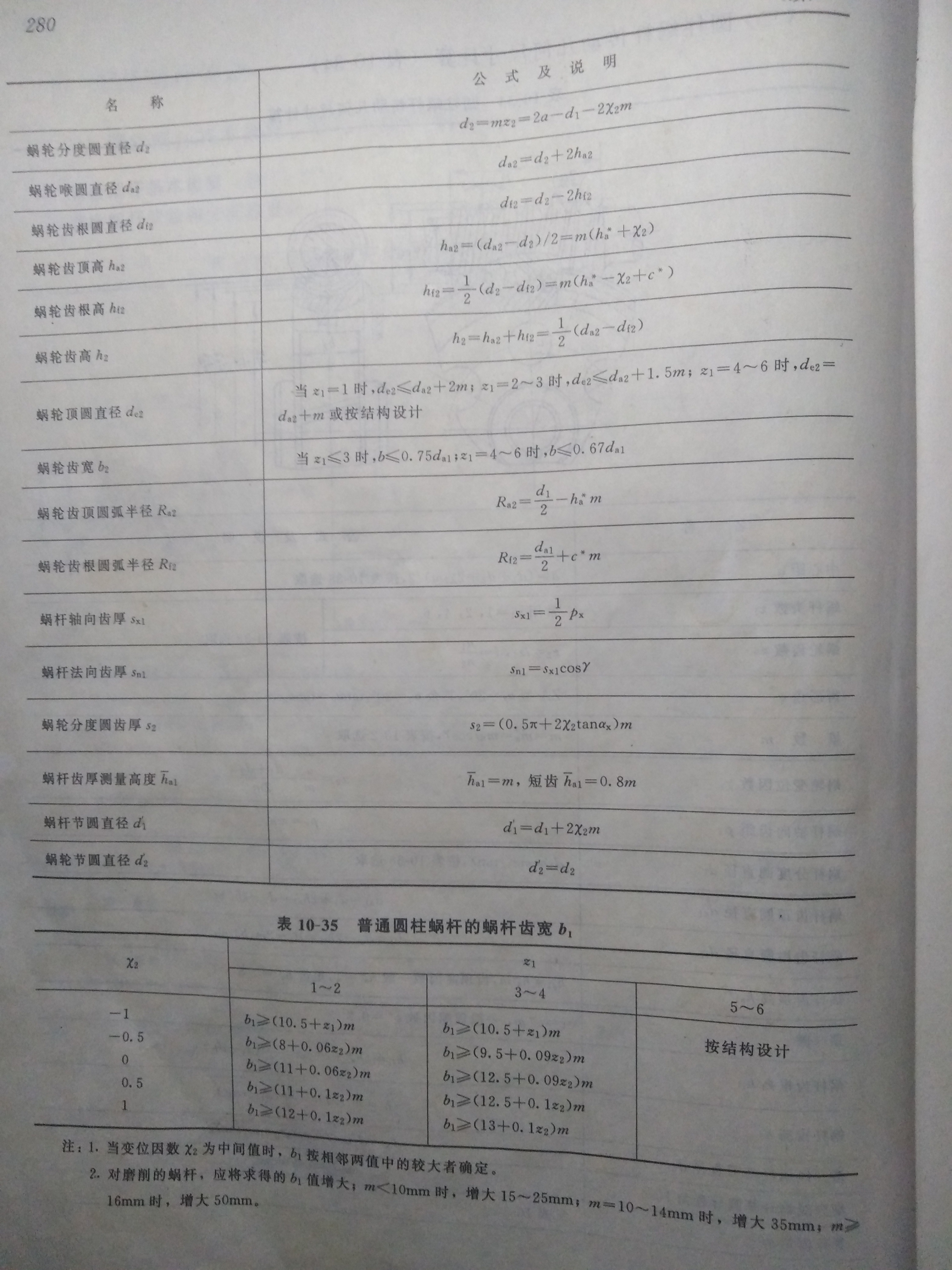

蜗杆齿宽:b1=2.5*m*(z2+1)^0.5

蜗杆螺牙分度圆轴向弦齿厚:sx1=0.5*m*pai

蜗杆螺牙分度圆示向弦齿厚:sn1=0.5*pai*m*cos(r)

蜗杆螺牙法向测齿高度:hcn1=m+0.5*sn1*tang(0.5*asin(sn1*sin(r)^2/d1))

测棒直径:dm=1.67*m

蜗杆跨棒距:md1=d1-(px1-0.5*pai*m)*cos(r)/tang(angle)+dm*(1/sin(angle)+1)

蜗轮分度圆螺旋角:B2=r1

蜗轮中圆螺旋角:Bm2=r

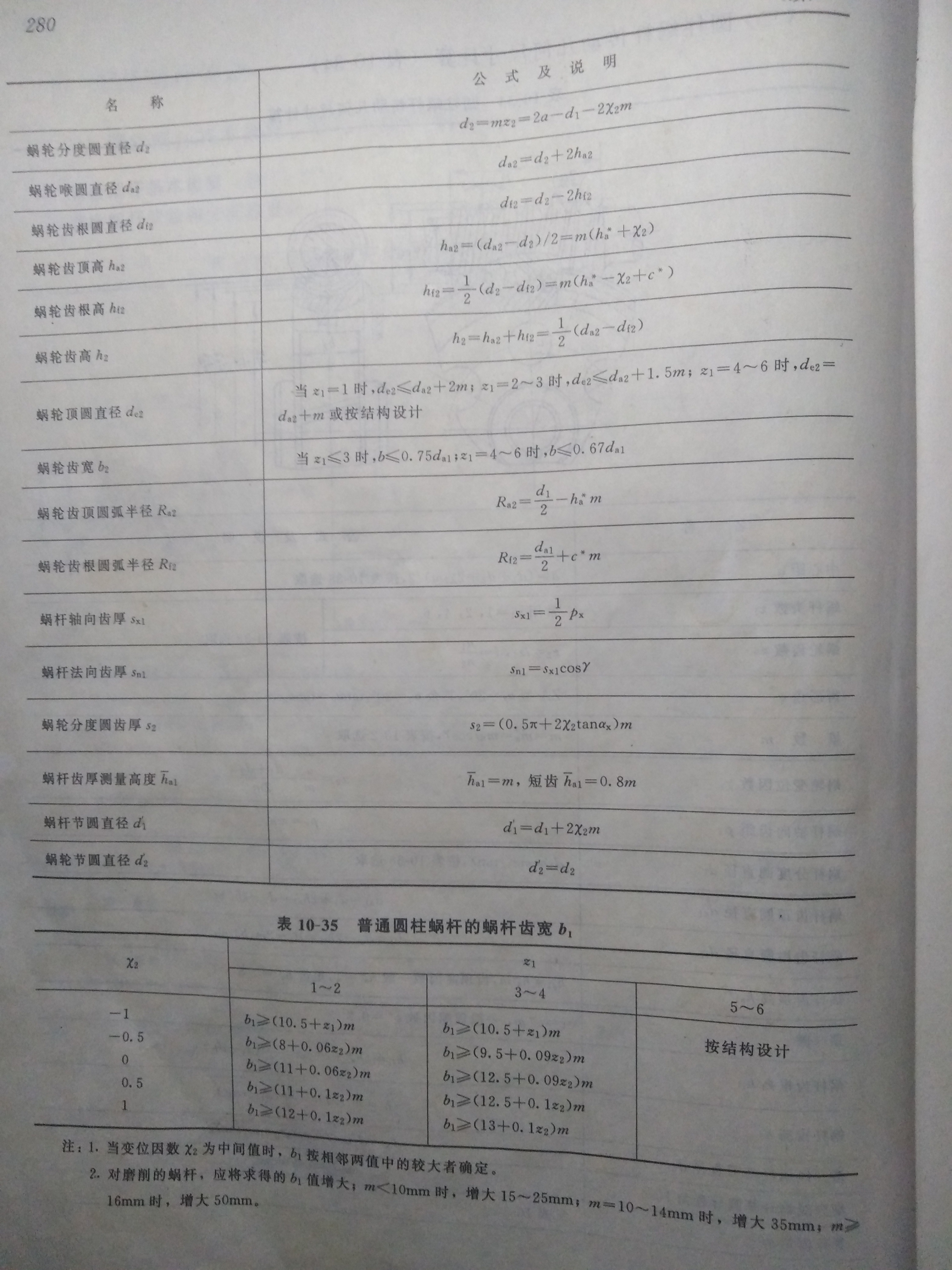

蜗轮分度圆直径:d2=m*z2

蜗轮中圆直径:dm2=d2+2*m*x2

蜗轮齿顶高:ha2=(1+x2)*m

蜗轮齿根高:hf2=(1.2-x2)*m

蜗轮全齿高:h2=ha2+hf2

蜗轮齿顶圆直径:da2=d2+ha2*2

蜗轮齿根圆直径:df2=d2-2*hf2

蜗轮外圆直径:de2=da2+m

蜗轮齿宽:b2=2*m*(0.5+(q+1)^0.5)

蜗轮齿宽包角:xita=2*asin(b2/d1)

蜗轮喉圆半径:rg2=A-0.5*da2

db2=d2*cos(angle)

端面重合度:ea=(0.5*(da2^2-db2^2)^0.5+m*(1-x2)/sin(angle)-0.5*d2*sin(angle))/(pai*m*cos(angle))

蜗杆转速:n1=2000

分度圆处滑动速度:vs=pai*d1*n1/(6*10000*cos(r))

计算结果:

D:\普通圆柱蜗杆传动几何尺寸计算.txt

普通圆柱蜗杆传动几何尺寸计算

(轴交角90度,已知中心距)

啮合中心距:A=95 = [ 95 ]

蜗杆轴向模数:M=5 = [ 5 ]

蜗杆头数:Z1=1 = [ 1 ]

蜗杆分度圆直径:D1=40 = [ 40 ]

蜗轮齿数:Z2=30 = [ 30 ]

蜗轮分度圆直径:D2=M*Z2 = [ 150 ]

蜗杆直径系数:Q=D1/M = [ 8.0 ]

齿数比:U=Z2/Z1 = [ 30.0 ]

蜗轮变位系数:X2=A/M-0.5*(Q+Z2) = [ 0.0 ]

蜗杆分度圆柱导程角:R1=ATAN(Z1/Q) = [ 7.12502 ]

法向模数:MN=M*COS(R1) = [ 4.96139 ]

蜗杆轴向齿距:PX1=PI*M = [ 15.708 ]

蜗杆螺旋线导程:PZ1=PX1*M = [ 78.5398 ]

蜗杆轴向齿形角:ANGLES=20 = [ 20 ]

蜗杆节圆直径:D_1=(Q+2*X2)*M = [ 40.0 ]

蜗杆节圆柱导程角:R=ATAN(Z1/(Q+2*X2)) = [ 7.12502 ]

渐开线蜗杆:

基圆柱导程角:RB=ACOS(COS(ANGLES)*COS(R)) = [ 21.1822 ]

基圆直径:DB1=Z1*M/TANG(RB) = [ 12.9027 ]

法向基节:PBM=PI*M*COS(RB) = [ 14.6467 ]

蜗杆齿顶高:HA1=M = [ 5 ]

蜗杆齿根高:HF1=1.2*M = [ 6.0 ]

蜗杆全齿高:H1=HA1+HF1 = [ 11.0 ]

顶隙:C1=0.2*M = [ 1.0 ]

齿根圆角半径:PF=0.3*M = [ 1.5 ]

蜗杆齿顶圆直径:DA1=D1+2*HA1 = [ 50 ]

蜗杆齿根圆直径:DF1=D1-HF1*2 = [ 28.0 ]

蜗杆齿宽:B1=2.5*M*(Z2+1)^0.5 = [ 69.5971 ]

蜗杆螺牙分度圆轴向弦齿厚:SX1=0.5*M*PAI = [ 7.85398 ]

蜗杆螺牙分度圆示向弦齿厚:SN1=0.5*PAI*M*COS(R) = [ 7.79333 ]

蜗杆螺牙法向测齿高度:HCN1=M+0.5*SN1*TANG(0.5*ASIN(SN1*SIN(R)^2/D1)) = [ 5.00584 ]

测棒直径:DM=1.67*M = [ 8.35 ]

蜗杆跨棒距:MD1=D1-(PX1-0.5*PAI*M)*COS(R)/TANG(ANGLES)+DM*(1/SIN(ANGLES)+1) = [ 51.3518 ]

蜗轮分度圆螺旋角:B2=R1 = [ 7.12502 ]

蜗轮中圆螺旋角:BM2=R = [ 7.12502 ]

蜗轮分度圆直径:D2=M*Z2 = [ 150 ]

蜗轮中圆直径:DM2=D2+2*M*X2 = [ 150.0 ]

蜗轮齿顶高:HA2=(1+X2)*M = [ 5.0 ]

蜗轮齿根高:HF2=(1.2-X2)*M = [ 6.0 ]

蜗轮全齿高:H2=HA2+HF2 = [ 11.0 ]

蜗轮齿顶圆直径:DA2=D2+HA2*2 = [ 160.0 ]

蜗轮齿根圆直径:DF2=D2-2*HF2 = [ 138.0 ]

蜗轮外圆直径:DE2=DA2+M = [ 165.0 ]

蜗轮齿宽:B2=2*M*(0.5+(Q+1)^0.5) = [ 35.0 ]

蜗轮齿宽包角:XITA=2*ASIN(B2/D1) = [ 122.09 ]

蜗轮喉圆半径:RG2=A-0.5*DA2 = [ 15.0 ]

DB2=D2*COS(ANGLES) = [ 140.954 ]

端面重合度:EA=(0.5*(DA2^2-DB2^2)^0.5+M*(1-X2)/SIN(ANGLES)-0.5*D2*SIN(ANGLES))/(PAI*M*

COS(ANGLES)) = [ 1.81716 ]

蜗杆转速:N1=2000 = [ 2000 ]

分度圆处滑动速度:VS=PAI*D1*N1/(6*10000*COS(R)) = [ 4.22139 ]

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

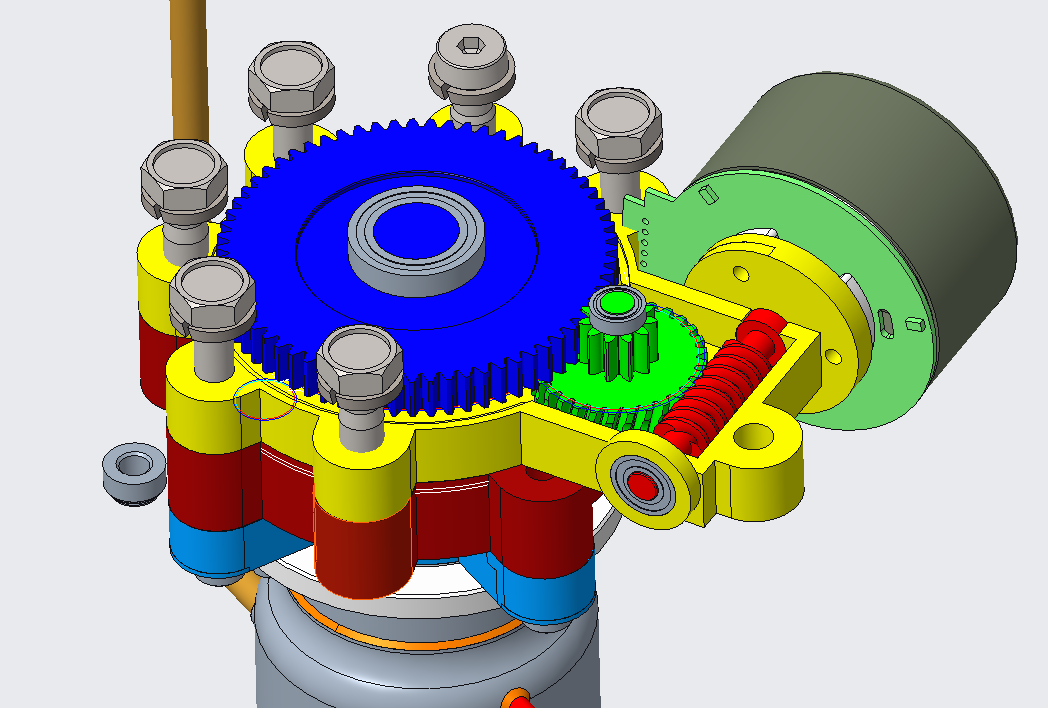

除支持以上ARX函数外,还支持所有的lisp函数以及用户自定义的lisp函数.能调用自定义的LISP函数,等于是一个开放的平台.LISP函数相当于子程序,可以不断地增加函数.任何人都可 增加自定义的LISP函数.这就使这平台变得无穷大.

(INV 20)=0.0149044 ;渐开线函数

(AINV 0.01)=17.5768 ;反渐开线函数

(atang x y)=atan(y/x) ;反正切函数,The range of angles returned is 0 to 360 degrees.

(atang 2 3)=56.3099

(atang -2 3)=123.69

(atang -2 -3)=236.31

(atang 2 -3)=303.69

(min 2 3 5)=2

......

lisp函数需在前面注明lisp.例如:

LISP: AT=(AINV A1)

LISP: GWORK=(MIN GW1 GW2)

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~`

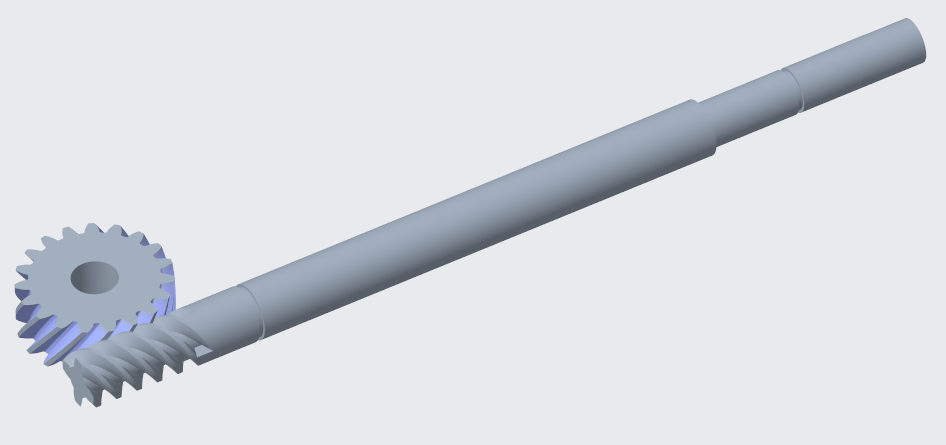

D:\外啮合渐开线圆柱齿轮传动计算.txt

外啮合渐开线圆柱齿轮传动计算

--------给定变位系数

输入数据

1 模数: MN=5 = [ 5 ]

2 齿数: Z1=25 = [ 25 ]

Z2=65 = [ 65 ]

3 螺旋角: HELIX=9.5 = [ 9.5 ]

4 基本齿廓

齿形角: AN=20 = [ 20 ]

齿顶高系数: HA_M=1.0 = [ 1.0 ]

径向间隙系数: C_M=0.25 = [ 0.25 ]

齿根圆角半径系数: P_M=0.38 = [ 0.38 ]

5 变位系数: X1=0.3 = [ 0.3 ]

X2=0.1 = [ 0.1 ]

6 精度等级: PGRADE=7 = [ 7 ]

7 齿宽: GW1=105.0 = [ 105.0 ]

GW2=100.0 = [ 100.0 ]

8 工作齿宽:

LISP:GW_WORK=(MIN GW1 GW2) = [ 100.0 ]

9 当量齿数: ZV1=Z1/(COS(HELIX)^3) = [ 26.0575 ]

ZV2=Z2/(COS(HELIX)^3) = [ 67.7494 ]

主要几何参数计算

1 分度(标准)中心距:A_BZ=(Z1+Z2)*MN/2/COS(HELIX) = [ 228.129 ]

2 变位系数和:XSUM=X1+X2 = [ 0.4 ]

3 端面齿形角:AT=ATAN(TANG(AN)/COS(HELIX)) = [ 20.2556 ]

4 端面啮合角:

;at1=ainv[2*xsum*tang(an)/(z1+z2)+inv(at)]

LISP:INVAT=(INV AT) = [ 0.0155037 ]

INVAT1=2*XSUM*TANG(AN)/(Z1+Z2)+INVAT = [ 0.018739 ]

LISP:AT1=(AINV INVAT1) = [ 21.5274 ]

5 中心距变动系数:

Y=(Z1+Z2)/2/COS(HELIX)*(COS(AT)-COS(AT1))/COS(AT1) = [ 0.388212 ]

6 补偿变位系数: DETA_Y=XSUM-Y = [ 0.0117882 ]

7 工作中心距: A_WORK=A_BZ+MN*Y = [ 230.07 ]

8 分度圆直径: D1=MN*Z1/COS(HELIX) = [ 126.738 ]

D2=MN*Z2/COS(HELIX) = [ 329.519 ]

9 齿数比(传动比): U=Z2/Z1 = [ 2.6 ]

10 节圆直径: D_NODE1=2*A_WORK/(U+1) = [ 127.817 ]

D_NODE2=2*A_WORK*U/(U+1) = [ 332.323 ]

11 齿顶圆直径: DA1=D1+2*(HA_M+X1-DETA_Y)*MN = [ 139.62 ]

DA2=D2+2*(HA_M+X2-DETA_Y)*MN = [ 340.401 ]

12 齿根圆直径: DF1=D1-2*(HA_M+C_M-X1)*MN = [ 117.238 ]

DF2=D2-2*(HA_M+C_M-X2)*MN = [ 318.019 ]

13 齿高: H1=(DA1-DF1)/2 = [ 11.1911 ]

H2=(DA2-DF2)/2 = [ 11.1911 ]

14 法面分度圆齿厚: SN1=(PI/2+2*X1*TANG(AN))*MN = [ 8.94589 ]

SN2=(PI/2+2*X2*TANG(AN))*MN = [ 8.21795 ]

15 基圆直径: DB1=D1*COS(AT) = [ 118.9 ]

DB2=D2*COS(AT) = [ 309.141 ]

16 基圆螺旋角: BB=ASIN(SIN(HELIX)*COS(AN)) = [ 8.92225 ]

齿厚测量尺寸计算

1 固定弦齿厚:

S_C1=MN*(PI/2*COS(AN)^2+X1*SIN(2*AN)) = [ 7.89942 ]

S_C2=MN*(PI/2*COS(AN)^2+X2*SIN(2*AN)) = [ 7.25663 ]

2 固定弦齿高:

H_C1=0.5*(DA1-D1-S_C1*TANG(AN)) = [ 5.00348 ]

H_C2=0.5*(DA2-D2-S_C2*TANG(AN)) = [ 4.12046 ]

3 分度圆弦齿厚:

;deta1=tod[pi/2/z1+2*x1*tang(an)/z1]*[cos(helix)^3]= 3.600000

DETA1=(PI/2/Z1+2*X1*TANG(AN)/Z1)*(COS(HELIX)^3) = [ 0.0686628 ]

DETA1=DETA1*180.0/PI = [ 3.93409 ] ;转化为角度

;deta2=tod[pi/2/z2+2*x2*tang(an)/z2]*[cos(helix)^3]= 1.384615

DETA2=(PI/2/Z2+2*X2*TANG(AN)/Z2)*(COS(HELIX)^3) = [ 0.0242599 ]

DETA2=DETA2*180.0/PI = [ 1.38999 ] ;转化为角度

齿厚:

S_1=MN*Z1*SIN(DETA1)/(COS(HELIX)^3) = [ 8.93886 ]

S_2=MN*Z2*SIN(DETA2)/(COS(HELIX)^3) = [ 8.21715 ]

4 分度圆弦齿高:

;ha_1=0.5*{da1-[cos(deta1)-sin(helix)^2]/[cos(helix)^2]*d1}= 5.123329

HA1=0.5*(DA1-(COS(DETA1)-SIN(HELIX)^2)/(COS(HELIX)^2)*D1) = [ 6.59456 ]

;ha_2=0.5*{da2-[cos(deta2)-sin(helix)^2]/[cos(helix)^2]*d2}= 5.047448

HA2=0.5*(DA2-(COS(DETA2)-SIN(HELIX)^2)/(COS(HELIX)^2)*D2) = [ 5.4909 ]

5 跨齿数:

LISP:INVAT=(INV AT) = [ 0.0155037 ]

LISP:INVAN=(INV AN) = [ 0.0149044 ]

Z11=Z1*INVAT/INVAN = [ 26.0053 ]

Z22=Z2*INVAT/INVAN = [ 67.6137 ]

K1=TRUNC(Z11/180*ACOS(Z11*COS(AN)/(Z11+2*X1))+0.5) = [ 3 ]

K2=TRUNC(Z22/180*ACOS(Z22*COS(AN)/(Z22+2*X2))+0.5) = [ 8 ]

6 公法线长度:

;w1=mn*cos(an)*[pi*(k1-0.5)+z1*inv(at)+2*x1*tang(an)]= 38.652335

;w2=mn*cos(an)*[pi*(k2-0.5)+z2*inv(at)+2*x2*tang(an)]= 115.256729

W1=MN*COS(AN)*(PI*(K1-0.5)+Z1*INVAT+2*X1*TANG(AN)) = [ 39.7488 ]

W2=MN*COS(AN)*(PI*(K2-0.5)+Z2*INVAT+2*X2*TANG(AN)) = [ 115.782 ]

6 量棒(球)跨距M值计算:

量棒直径: DP=TRUNC(1.728*MN) = [ 8 ]

;或自定直径:dp=9.0

量棒中心所在圆上的压力角:

LISP:INVAT=(INV AT) = [ 0.0155037 ]

A1=DP/(Z1*MN*COS(AN))+INVAT-PI/2/Z1+2*X1*TANG(AN)/Z1 = [ 0.0295145 ]

A2=DP/(Z2*MN*COS(AN))+INVAT-PI/2/Z2+2*X2*TANG(AN)/Z2 = [ 0.0186527 ]

LISP:AD1=(AINV A1) = [ 24.8779 ]

LISP:AD2=(AINV A2) = [ 21.4956 ]

量棒(球)跨距M值:

;M1=d1*cos(at)/cos(ad1)+dp ;z1为偶数

M1=D1*COS(AT)/COS(AD1)*COS(90/Z1)+DP = [ 138.803 ] ;Z1为奇数

;M2=d2*cos(at)/cos(ad2)+dp ;z2为偶数

M2=D2*COS(AT)/COS(AD2)*COS(90/Z2)+DP = [ 340.153 ] ;Z2为奇数

传动质量指标计算

1 齿顶点压力角:

AA1=ACOS(DB1/DA1) = [ 31.6141 ]

AA2=ACOS(DB2/DA2) = [ 24.7469 ]

2 端面重合度:

EA=0.5/PI*(Z1*TANG(AA1)+Z2*TANG(AA2)-(Z1+Z2)*TANG(AT1)) = [ 1.56737 ]

3 斜齿轮齿顶螺旋角:

BA1=ATAN(DA1/D1*TANG(HELIX)) = [ 10.4453 ]

BA2=ATAN(DA2/D2*TANG(HELIX)) = [ 9.80773 ]

4 法面齿顶厚:

;san1=da1*{[0.5*pi+2*x1*tan(an)]/z1+inv(at)-inv(aa1)}*cos(Ba1)= 3.599097

;san2=da2*{[0.5*pi+2*x2*tan(an)]/z2+inv(at)-inv(aa2)}*cos(Ba2)= 3.948438

LISP : INVAT=(INV AT) = [ 0.0155037 ]

LISP : INVAA1=(INV AA1) = [ 0.0637734 ]

LISP : INVAA2=(INV AA2) = [ 0.0290258 ]

SAN1=DA1*((0.5*PI+2*X1*TANG(AN))/Z1+INVAT-INVAA1)*COS(BA1) = [ 3.1989 ]

SAN2=DA2*((0.5*PI+2*X2*TANG(AN))/Z2+INVAT-INVAA2)*COS(BA2) = [ 3.94591 ]

5 滑动率:

η1=(1+U)*(TANG(AA2)-TANG(AT1))/(TANG(AT1)-U*(TANG(AA2)-TANG(AT1))) = [ 1.07986 ]

η2=(1+U)*(TANG(AA1)-TANG(AT1))/(U*TANG(AT1)-(TANG(AA1)-TANG(AT1))) = [ 0.98927 ]

~~~~~~~~~~~~~~~~~~~~~

普通圆柱蜗杆传动几何尺寸计算-(已知蜗杆齿顶圆直径8)

(轴交角90度,已知蜗杆齿顶圆直径)

;啮合中心距:A=(d1+d2+2* x2* m)/2.0

;啮合中心距:A=20.0

蜗杆轴向模数:M=1

蜗杆头数:Z1=2

蜗轮齿数:Z2=29

蜗轮分度圆直径:D2=M*Z2 = [ 29 ]

蜗杆齿顶高:HA1=M = [ 1 ]

蜗杆齿根高:HF1=1.2*M = [ 1.2 ]

蜗杆齿顶圆直径:DA1=8 = [ 8 ] ;D1+2*HA1

蜗杆分度圆直径:D1=DA1-2*HA1 = [ 6 ]

蜗杆直径系数:Q=D1/M = [ 6.0 ]

齿数比:U=Z2/Z1 = [ 14.5 ]

;蜗轮变位系数:x2=A/m-0.5*(q+z2)

;蜗轮变位系数:X2= A/m-0.5*(d1+d2)/ m

蜗轮变位系数:X2=-0.1

啮合中心距:A=(D1+D2+2* X2* M)/2.0 = [ 17.4 ]

蜗杆分度圆柱导程角:R1=ATAN(Z1/Q) = [ 18.4349 ]

法向模数:MN=M*COS(R1) = [ 0.948683 ]

蜗杆轴向齿距:PX1=PI*M = [ 3.14159 ]

蜗杆螺旋线导程:PZ1=PX1*M = [ 3.14159 ]

蜗杆轴向齿形角:ANGLE=20 = [ 20 ]

蜗杆节圆直径:D_1=(Q+2*X2)*M = [ 5.8 ]

蜗杆节圆柱导程角:R=ATAN(Z1/(Q+2*X2)) = [ 19.0256 ]

渐开线蜗杆:

基圆柱导程角:RB=ACOS(COS(ANGLE)*COS(R)) = [ 27.3321 ]

基圆直径:DB1=Z1*M/TANG(RB) = [ 3.86961 ]

法向基节:PBM=PI*M*COS(RB) = [ 2.79087 ]

蜗杆全齿高:H1=HA1+HF1 = [ 2.2 ]

顶隙:C1=0.2*M = [ 0.2 ]

齿根圆角半径:PF=0.3*M = [ 0.3 ]

蜗杆齿顶圆直径:DA1=D1+2*HA1 = [ 8 ]

蜗杆齿根圆直径:DF1=D1-HF1*2 = [ 3.6 ]

蜗杆齿宽:B1=2.5*M*(Z2+1)^0.5 = [ 13.6931 ]

蜗杆螺牙分度圆轴向弦齿厚:SX1=0.5*M*PAI = [ 1.5708 ]

蜗杆螺牙分度圆示向弦齿厚:SN1=0.5*PAI*M*COS(R) = [ 1.48499 ]

蜗杆螺牙法向测齿高度:HCN1=M+0.5*SN1*TANG(0.5*ASIN(SN1*SIN(R)^2/D1)) = [ 1.00977 ]

测棒直径:DM=1.67*M = [ 1.67 ]

蜗杆跨棒距:MD1=D1-(PX1-0.5*PAI*M)*COS(R)/TANG(ANGLE)+DM*(1/SIN(ANGLE)+1) = [ 8.47278 ]

蜗轮分度圆螺旋角:B2=R1 = [ 18.4349 ]

蜗轮中圆螺旋角:BM2=R = [ 19.0256 ]

蜗轮分度圆直径:D2=M*Z2 = [ 29 ]

蜗轮中圆直径:DM2=D2+2*M*X2 = [ 28.8 ]

蜗轮齿顶高:HA2=(1+X2)*M = [ 0.9 ]

蜗轮齿根高:HF2=(1.2-X2)*M = [ 1.3 ]

蜗轮全齿高:H2=HA2+HF2 = [ 2.2 ]

蜗轮齿顶圆直径:DA2=D2+HA2*2 = [ 30.8 ]

蜗轮齿根圆直径:DF2=D2-2*HF2 = [ 26.4 ]

蜗轮外圆直径:DE2=DA2+M = [ 31.8 ]

蜗轮齿宽:B2=2*M*(0.5+(Q+1)^0.5) = [ 6.2915 ]

蜗轮齿宽包角:XITA=2*ASIN(B2/D1) = [ 180.0 ]

蜗轮喉圆半径:RG2=A-0.5*DA2 = [ 2.0 ]

DB2=D2*COS(ANGLE) = [ 27.2511 ]

端面重合度:EA=(0.5*(DA2^2-DB2^2)^0.5+M*(1-X2)/SIN(ANGLE)-0.5*D2*SIN(ANGLE))/(PAI*M*COS(ANGLE)) = [ 1.84056 ]

蜗杆转速:N1=2000

分度圆处滑动速度:VS=PAI*D1*N1/(6*10000*COS(R)) = [ 0.664625 ]

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

以CAD对文本文件的计算功能进行圆柱齿轮副的设计及强度校核:

http://aero-cad.com/view-1093.html